Introduction to Total Hip Arthroplasty (THA)

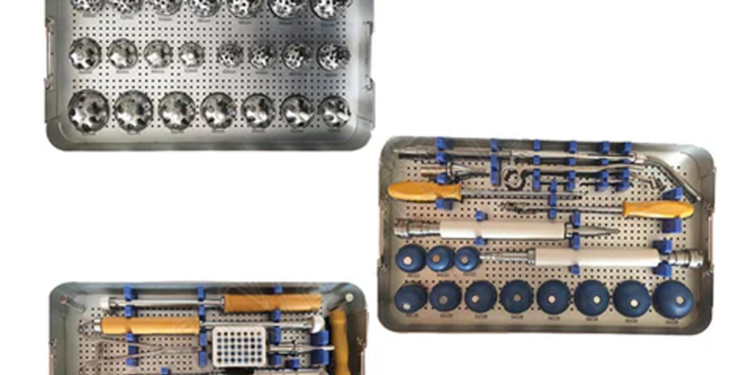

A total replacement of the hip is among the most effective orthopedic procedures that has been developed. Patients benefit from the restoration of mobility and freedom from discomfort. It’s for surgeons a very precise procedure in which precision is the key to success. The core of this precision is the Total Hip Prosthesis Instruments Set–a carefully designed set of tools that are designed to make bone more stable and align implants to make sure that the implant is stable over time.

What Is a Total Hip Prosthesis?

The total hip prosthesis is a replacement for the femoral head as well as the socket for the acetabular joint. The objective is easy in principle: restore smooth, pain-free motion; however, achieving that goal relies in large part on how precisely the implants are put in.

Role of Instrument Sets in Hip Replacement Surgery

Consider the instrument set as a toolbox and the roadmap. Even the top implant may fail if the devices that are guiding its placement aren’t precise, as well as durability and ergonomic design issues.

Understanding the Total Hip Prosthesis Instruments Set

What Comes in a Standard Hip Prosthesis Instrument Set?

A complete set typically comprises:

- Acetabular reamers

- Broaches and rasps on the femur

- Trial components

- Alignment guides

- Extractors and Impactors

- Measurement and depth gauges

Each instrument has a distinct function, and when they are used together, they provide a regulated process that is repeatable and predictable.

Modular vs Comprehensive Instrument Sets

Modular sets let hospitals adapt instruments to suit the implant system and surgeon preferences, and comprehensive sets provide all-in-one solutions for large-volume centers.

Core Components of the Instrument Set

Acetabular Preparation Instruments

These tools form the pelvic socket to accommodate the acetabular cup.

Reamers and Reamer Handles

Acetabular reamers can be precisely machined to create a hemispherical hollow with precise dimensions. The cutting edges have to be strong, sharp and ideally concentric.

Femoral Preparation Instruments

Rasps, Broaches, and Handles

Femoral rasps form the femoral canal to match the stem of the implant. This procedure requires precision in order to guarantee stability and proper transfer of load.

Implant Insertion and Extraction Tools

Impactors exert controlled force, extractors enable secure removal of trials and implants without harming bone.

Alignment, Trial, and Measuring Instruments

Necks, test heads and alignment guides aid surgeons in evaluating the range of leg length, motion and joint stability before surgical implantation.

Materials Used in Total Hip Prosthesis Instruments

Medical-Grade Stainless Steel

Most instruments are made of stainless steel with high strength, such as AISI either 420 or 440, which offer superior toughness, corrosion resistance and sterilization.

Titanium and Titanium Alloys

Titanium instruments are less heavy and less fatigue-inducing for surgeons, particularly during lengthy procedures. They’re also non-magnetic, making them perfect for imaging environments that require advanced technology.

Cobalt-Chromium Components

In high wear areas, Cobalt-chromium alloys offer exceptional durability as well as wear-resistant.

Tungsten Carbide Reinforcements

High-stress contact points usually have tungsten carbide inserts that can extend the lifespan of instruments.

High-Performance Polymers

Handles and trial components could make use of medical-grade polymers to decrease weight and enhance handling.

Manufacturing Processes Behind Hip Instruments

Precision Forging and CNC Machining

Forging enhances structural integrity, while CNC machining ensures micron-level accuracy–non-negotiable in joint replacement surgery.

Heat Treatment and Stress Relief

A carefully controlled heat treatment can increase the strength of instruments without making them fragile.

Surface Finishing and Passivation

Matte or satin finishes decrease the reflection of light in the operating room. Passivation enhances the resistance to corrosion.

Laser Marking and Traceability

Laser-etched markings permit complete traceability, which aids in the management of inventory and compliance with regulations.

Engineering Precision and Tolerances

Why Micron-Level Accuracy Matters

Just a tiny millimeter of difference can impact joint biomechanics length of the leg, as well as implant durability.

Fit, Alignment, and Biomechanics

Correctly designed instruments can aid in re-creating the an ideal hip joint, reducing wear and improving the outcomes of patients.

Ergonomics and Surgeon Experience

Handle Design and Grip Optimization

Handles with contours and texture increase control and decrease hand strain.

Weight Balance and Fatigue Reduction

The instruments that are balanced feel similar to an extension of the surgeon’s hand. They are steady, as well as predictable and responsive.

Sterilization Compatibility and Reusability

Autoclave Resistance

Instruments need to endure repeated high-temperature sterilization cycles without deterioration.

Corrosion and Wear Considerations

The choice of materials and the surface treatment play an important role in the long-term durability.

Quality Control and Regulatory Standards

ISO, ASTM, and CE Compliance

Top-quality instrument sets meet ISO 13485, ASTM standards and CE marking specifications.

Inspection, Testing, and Validation

Tests for hardness, dimensional checks and functional trials guarantee security and consistency.

Durability and Lifecycle of Instrument Sets

High-Stress Zones and Reinforcement

Areas that are subjected to repeated impact or cutting are strengthened to avoid premature failure.

Maintenance and Refurbishment

Regular inspections and re-sharpening could dramatically extend the lifespan of instruments.

Cost Factors in Total Hip Instrument Sets

Raw Materials and Manufacturing Costs

Precision machining and advanced alloys can increase the cost of initial production, but also improve the value in the long term.

Long-Term Value vs Initial Investment

High-quality sets reduce replacement frequency and surgical complications–saving money over time.

Customization and Modular Design Trends

Surgeon-Specific Preferences

Customized handles and components that are modular are a part of individual surgical techniques.

Integrity With Implant Systems

Modern set-ups are typically designed to integrate seamlessly with particular implant brands.

Sustainability and Environmental Impact

Reusable vs Disposable Components

Reusable tools reduce pollution and waste.

Eco-Conscious Manufacturing Practices

Recycled and energy-efficient materials, as well as machining, are becoming the norm in industry.

Future Innovations in Hip Prosthesis Instruments

Smart Instruments and Navigation Integration

Sensors and tools that are navigation-ready improve the alignment and precision.

Additive Manufacturing (3D Printing)

3D printing allows rapid prototyping and intricate geometries that are not possible with traditional techniques.

Choosing the Right Total Hip Prosthesis Instruments Set

Hospital, Surgeon, and Patient Considerations

Case volume, experience of the surgeon and the complexity of the patient all affect the choice of instruments.

Balancing Precision, Cost, and Reliability

The best option is one that provides constant performance, without the need for excessive complications.

Conclusion

The Complete Hip Prosthesis Set of Instruments is more than just a set of tools. It’s an engineered system with precision that directly affects the surgical precision, long-term implant life, and the outcomes of patients. From the most advanced materials and strict tolerances to ergonomic designs and a rigorous quality control system, every aspect is important. Investing in top-quality equipment will result in more effective surgeries and healthier lives.

Frequently Asked Questions (FAQs)

1. How long will a complete hip instrument set usually last?

If it is maintained properly, high-quality setups can last for a long time and undergo many procedures.

2. Are titanium instruments superior to those made of stainless steel?

The titanium is a lot lighter and less fatigue-prone, stainless steel is extremely durable at a cost that is lower.

3. What makes modular instrument sets well-liked?

They offer flexibility and customization, as well as compatibility with various implant systems.

4. What is the importance of alignment accuracy?

Very important. Even small mistakes can impact the biomechanics of the joint and extend the lifespan of the implant.

5. Can hip instruments be repaired?

Yes, a lot of instruments can be repaired and re-sharpened to extend their lifespan.