Modern electrical systems are expected to do more than simply turn equipment on and off. You rely on them to operate safely, respond quickly to control signals, and withstand years of repeated use without failure. Whether you are dealing with industrial machinery, large buildings, or automated processes, these demands place heavy responsibility on the components hidden inside control panels. One device that consistently meets these requirements is the contactor relay.

A contactor relay is widely used in electrical systems where reliable switching, electrical isolation, and structured control logic are essential. As automation and electrification continue to expand worldwide, understanding where and why this device is preferred helps you better evaluate system design choices, maintenance needs, and safety considerations. This article explores the key electrical applications where a contactor relay is commonly used and explains the practical reasons behind its widespread adoption.

Understanding the Role of a Contactor Relay

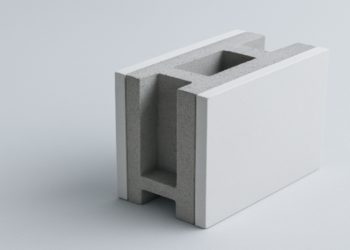

At its core, a contactor relay is an electromechanical switching device that operates by energizing a coil to open or close electrical contacts. Unlike simple relays intended for light-duty signaling, contactor relays are designed for use in structured control circuits that require frequent operation and dependable performance. You will typically find them handling control signals rather than directly switching high-power loads.

One of the most important functions of a contactor relay is electrical isolation. By separating low-voltage control circuits from higher-voltage power circuits, it reduces the risk of electrical faults affecting sensitive components or operators. This isolation also makes troubleshooting and maintenance safer and more manageable, especially in complex systems where multiple circuits interact.

Why Contactor Relays Are Preferred Over Standard Relays

In many applications, a standard relay may appear sufficient at first glance. However, as system complexity increases, limitations quickly emerge. A contactor relay is preferred because it is built for higher mechanical endurance and more consistent performance under frequent switching conditions.

These devices are commonly used where control logic must interact with multiple components at once. Their contact arrangements allow you to design interlocks, sequencing, and fail-safe operations more effectively. Additionally, the physical spacing and insulation of contacts are typically better suited for industrial environments, helping maintain reliability even when electrical noise, vibration, or temperature variation is present.

Industrial Control Panels and Automation Systems

Industrial control panels are among the most common places where you will encounter a contactor relay. These panels serve as the central nervous system of automated operations, coordinating sensors, controllers, and actuators to perform precise tasks.

In automation systems, contactor relays often act as intermediaries between programmable controllers and field devices. A controller sends a low-power signal, and the relay responds by switching control circuits that initiate actions such as starting equipment, enabling processes, or triggering alarms. This layered approach protects sensitive electronics while allowing flexible expansion of the control system as operational needs evolve.

Power Distribution and Control Coordination

Within control panels, contactor relays also play a supporting role in power distribution. While they do not usually carry the main load current, they control the devices that do. This allows you to manage power circuits remotely, coordinate startup sequences, and prevent unsafe operating conditions.

For example, a relay can be used to ensure that certain equipment cannot energize unless specific conditions are met, such as proper sequencing or confirmed shutdown of other systems. This type of coordination improves overall system safety and reduces the likelihood of equipment damage caused by incorrect operation.

Motor Control and Machinery Applications

Electric motors are central to industrial and commercial operations, and controlling them safely requires more than direct switching. In motor control systems, a contactor relay is often used as part of the control logic that governs how and when motors start, stop, or change operating states.

Rather than handling motor current directly, the relay controls the signals that energize power contactors and protective devices. This separation allows you to design motor control circuits that are easier to modify and maintain. If operating requirements change, control logic can often be adjusted without replacing high-power components.

Integration With Protection Devices

Motor-driven systems must also account for faults such as overloads or phase loss. Contactor relays are frequently integrated with protective devices to create coordinated responses to abnormal conditions. When a fault occurs, the relay can interrupt control signals, prevent automatic restarts, and signal the fault status to operators or monitoring systems.

This approach improves both safety and reliability. You gain clearer visibility into system behavior while reducing the risk of repeated faults that could shorten equipment lifespan or create hazardous conditions during maintenance.

Lighting Systems in Commercial and Industrial Facilities

Large-scale lighting systems present unique control challenges, especially in facilities with extensive floor space or multiple usage zones. In these environments, contactor relays are often used to centralize lighting control while keeping control circuits electrically isolated from lighting power circuits.

By using relays, you can manage lighting through schedules, sensors, or centralized control panels without running high-current wiring to every control point. This simplifies installation and makes it easier to adjust lighting strategies as building usage changes over time.

Building Automation and Energy Management

As buildings become smarter, the need for reliable control interfaces increases. In building automation systems, contactor relays help connect controllers with lighting, HVAC, and energy management equipment. Their role is to safely translate control signals into physical actions without exposing control electronics to higher voltages.

This modular approach supports scalability. As additional systems or zones are added, new relays can be incorporated without redesigning the entire control architecture. The result is a more adaptable and maintainable building infrastructure.

Specialized Control and Safety Circuits

Some electrical environments demand especially high levels of signal integrity and isolation. In areas with significant electrical noise or high-voltage equipment, contactor relays help protect control circuits from interference and unintended interactions.

They are also commonly used in safety-related circuits, where predictable behavior is essential. By providing clear separation between control logic and power equipment, relays support safer operation and easier compliance with electrical safety practices.

Low-Power Control in High-Voltage Environments

When low-power control systems operate near high-voltage equipment, careful design is required to minimize risk. A contactor relay allows you to keep operator interfaces and control electronics at safer voltage levels while still influencing high-energy systems indirectly.

This design philosophy reduces the likelihood of accidental exposure and simplifies compliance with electrical safety requirements. It also makes systems easier to inspect and service, since control components can often be accessed without interacting directly with power circuits.

Selection Considerations for Contactor Relays

CHINT offers reliable contactor relays suited for diverse applications providing robust options across voltage ratings and configurations. Choosing the right contactor relay involves more than matching voltage ratings. You should also consider contact configuration, expected switching frequency, and compatibility with other control devices. Mechanical endurance is particularly important in applications where frequent operation is expected.

Environmental factors also matter. Temperature, humidity, vibration, and available panel space can all influence performance and longevity. By accounting for these conditions during selection, you improve system reliability and reduce the likelihood of premature component failure.

Conclusion

A contactor relay is a foundational component in many modern electrical systems, valued for its ability to provide reliable switching, electrical isolation, and structured control logic. From industrial automation and motor control to lighting systems and building automation, it plays a critical role in applications where safety, flexibility, and durability are essential.

By understanding where contactor relays are preferred and how they function within larger systems, you gain clearer insight into electrical design choices and operational best practices. As electrical systems continue to grow more complex, the principles behind using a contactor relay remain the same: protect control circuits, support reliable operation, and enable systems that are easier to manage over time.

David Prior

David Prior is the editor of Today News, responsible for the overall editorial strategy. He is an NCTJ-qualified journalist with over 20 years’ experience, and is also editor of the award-winning hyperlocal news title Altrincham Today. His LinkedIn profile is here.

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)