Peripheral Milling

Peripheral or slab milling is a machining technique in which the cutter rotates parallel to the surface and cuts along its edge. It entails a cutter that is placed in parallel to the surface. The edges of the tool have teeth that excavate material gradually and with a high level of control, and provide a uniform quality of finish.

The primary types of peripheral milling are:

- Plain milling

- Up-milling,

- Down-milling

Each approach has its exclusive advantage for the particular material type and design. The proper selection of the method will aid in delivering dependable machining results. This guide will give you the directions on how peripheral milling operates. You will also learn its advantages and applications.

What Is Peripheral Milling?

Peripheral Milling Process

Peripheral milling is a type of custom CNC milling service. It involves a milling cutter that cuts away material on its outer edges. The cutter axis remains parallel to the workpiece. This allows long, continuous cuts on flat and slightly curved surfaces.

Several teeth on the circumference of the cutter divide the work and provide an increased rate of material removal and stability when machining. The best cutting will be dependent on the:

- Tool diameter

- Number of flutes

- Feed rate

The above factors dictate the chip shape, texture, and cutting performance. Due to the fine ridges caused by peripheral milling on the material, a secondary finish could be required on smooth and precision-critical surfaces.

Peripheral milling is mainly applied in the aerospace, automotive, and defence industries. It generates flat surfaces, slots, and complex shapes with uniform accuracy.

In contrast to face milling, peripheral milling removes material using the circumference of the cutter as opposed to the end of the tool.

What are the Basic Techniques of Peripheral Milling?

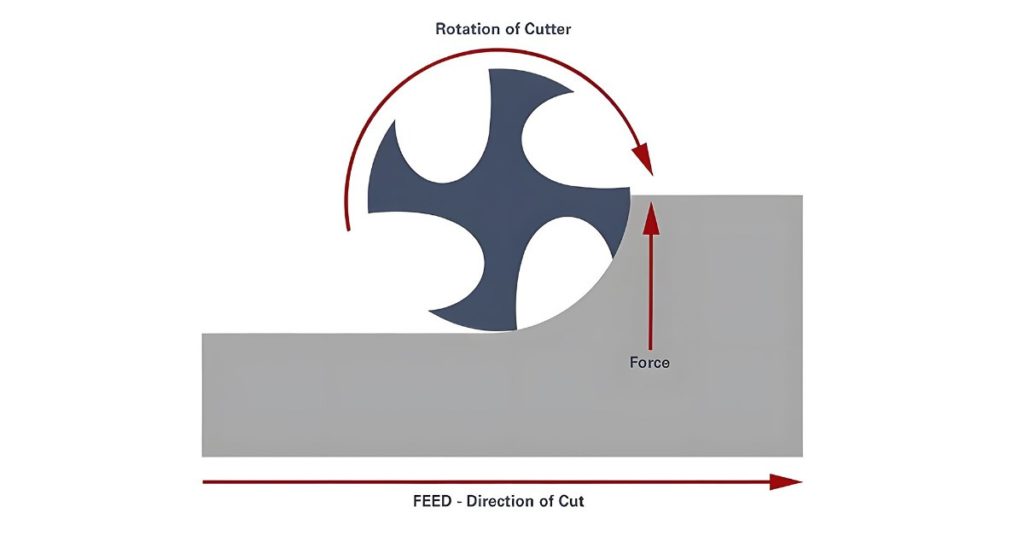

Peripheral milling operations take place in two significant ways;

- Up milling (Conventional)

- Down milling (Climb)

These techniques vary in cutting characteristics, chip forming, and material. Choosing an appropriate way determines high precision, tool life, and excellent surface finish.

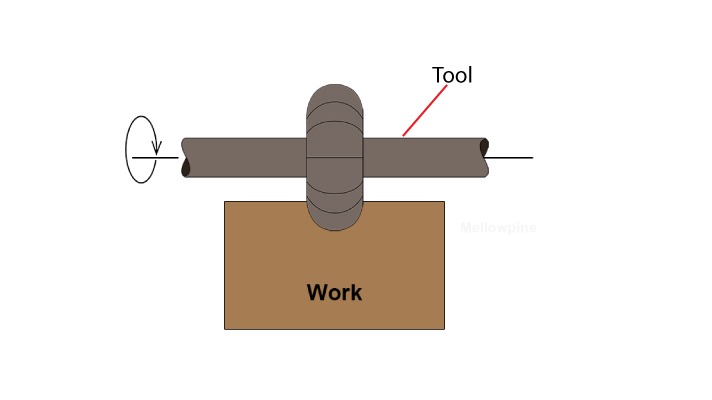

Up Milling (Conventional Milling)

Up Milling

In up milling, the tool rotates against the direction of the feed of the workpiece. It makes thin chips at the beginning and becomes thicker as the cut is continued, and an additional cutting force is necessary.

The workpiece can be raised with tangential forces. So, a firm fixture is needed. Up milling is suited to roughing hard metals such as steel, bronze, and brass. It effectively cuts material in large quantities and may produce a coarser finish and more tool wear.

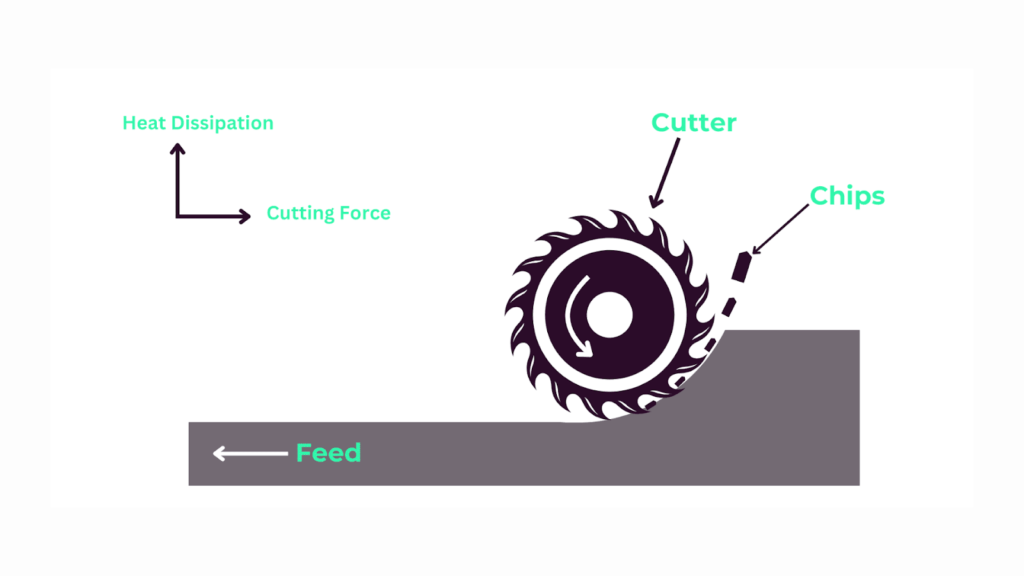

Down Milling (Climb Milling)

Climb Milling

In down milling, the cutter rotates in the same direction as the feed of the workpiece. It produces less friction, chips, and heat. The forces perpendicular to the workpiece cause the workpiece to press and hold the cut constant, and allow a higher feed rate. It is most suitable for the soft metals like aluminium.

Comparison of the Up and Down Milling

| Parameters | Up Milling | Down Milling |

| Cutter direction | Opposite to feed | Same as feed |

| Cutting force | High | Lower |

| Tangential forces | Lift workpiece | Press the workpiece down |

| Surface finish | Rougher | Smoother |

| Tool wear | Higher | Lower |

| Chip formation | Thickens along the cut | Thins along cut |

| Best use | Roughing, hard metals | Finishing, softer metals |

What are the Common Peripheral Milling Techniques?

In peripheral milling, the cutter cuts the material by its circumference, and its axis is parallel to the surface of the workpiece. The cutter configurations determine the cut quality, efficiency, and surface finish. Choosing the correct procedure is crucial to achieving optimal results.

Slab Milling

Slab milling utilizes a larger cylindrical cutter to quickly cut off material and carve flat surfaces. It works well when large areas need to be cut and the thickness needs to be reduced. It is commonly used to rough and prepare work pieces for finishing operations.

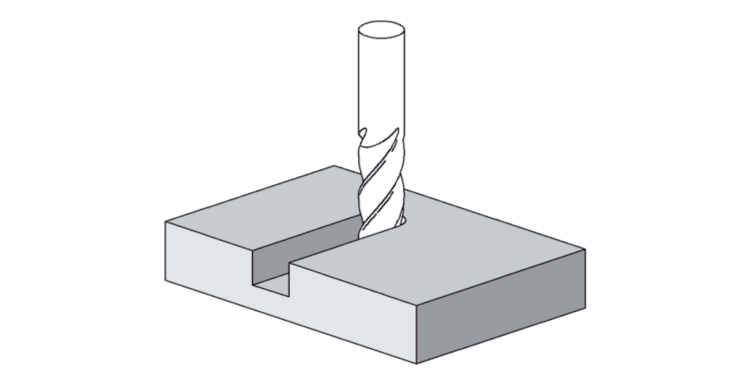

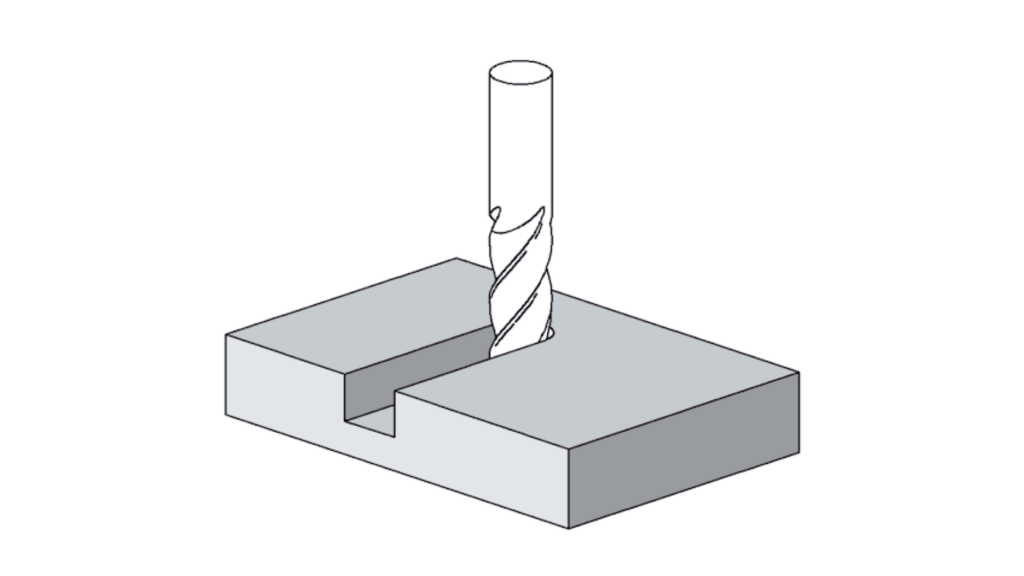

Slot Milling

Slot Milling

Grooves or channels are formed by slot milling. It is ideal for cutting keyways and narrow grooves. In slot milling, the cutter is carefully sized to avoid damaging nearby surfaces.

Side Milling

In Side milling, the cutter’s axis is parallel to the work surface. It provides flat vertical planes of the same size. It is applied to those parts where the position on the sides and the surface quality are critical.

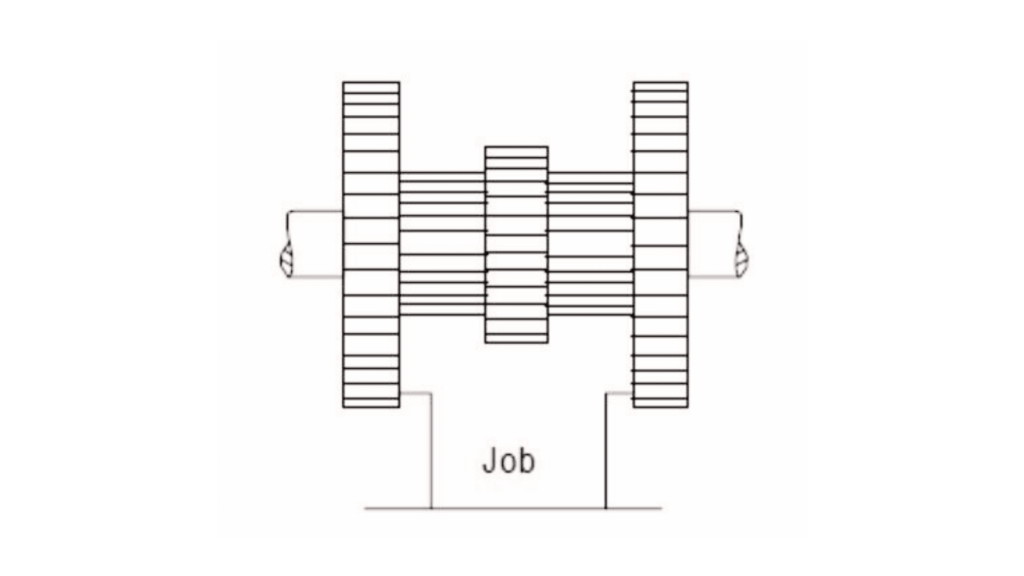

Gang Milling

Gang Milling

The gang milling process utilizes a set of cutters on the same arbor to mill multiple surfaces simultaneously. To the required width, spacers adjust the cutter positions. The process conserves machining time and is particularly suitable for parts with numerous parallel faces.

Straddle Milling

Straddle milling is similar to gang milling. The only difference is that it is designed to cut two parallel surfaces. There are two cutters on one arbor, so they are evenly spaced. The technique works well in shaping or two-slot operations, increasing the speed and accuracy.

Form Milling

Form milling is a process that creates complex patterns or outlines using custom-shaped cutters. It is applied to threads, recesses, and rounded ornamental profiles. Form milling enables precise designs that conventional cutters cannot achieve.

Common Peripheral Milling Cutters

- End Mills: End mills are used to cut the workpiece with sharp teeth that are helical in shape.

- Concave and Convex Cutters: Concave and convex cutters produce curved shapes on parts with the specified accuracy.

- Slab Milling Cutter: Slab milling cutters can remove enormous amounts of material to create smooth, flat surfaces.

- Staggered Milling Cutter: Staggered milling cutters cut deep using zig-zag flutes, which serve as a good method of milling without any stopping.

- Woodruff Cutter: Woodruff cutters are good at making keyways and clearing chips.

- Side Milling Cutter: Side milling cutters are applied to cut deep, angled, or vertical grooves.

- Hobbing cutters: Hobbing cutters cut splines and gear teeth.

Conclusion

So, the appropriate peripheral milling techniques keep the tools lasting longer and make machining easier. Choosing the correct cutters and technique will make parts more accurate and minimize wear.

By directing the feed correctly and removing the chips orderly, the production can be increased faster, and products come out with a uniform surface finish. The steps have made peripheral milling reliable and efficient in each project.

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)