Preface

Aluminum is lightweight and sturdy, but its high reflectivity and thermal conductivity make welding challenging. A laser welder can precisely control energy to create clean welds with minimal deformation. With advanced fiber laser technology, Dynalasers has developed high-performance handheld laser welders that deliver faster, more reliable aluminum welding and significantly improve efficiency.

Why Aluminum Welding Benefits from Laser Technology

In the field of aluminum laser welding, this technology stands out due to its various advantages, and thus has become the preferred process for many American aluminum processing manufacturers.

- Precision and Control

One of the greatest advantages of laser welding is its precision and controllability. Because the laser beam can be highly focused, it can accurately project heat onto the target area without over-heating the surrounding materials. For metals like thin aluminum sheets that are prone to deformation, or small parts with complex geometries, this precise positioning is particularly important.

- Speed and Efficiency

The greatest advantage of using a fiber laser welder to weld aluminum materials is that it is both fast and efficient. Compared with MIG or TIG welding, it can complete the joint welding much faster without any loss in quality. As a result, it not only shortens the production time but also helps enterprises save costs and improve overall efficiency.

- Strong Versatility

The versatility of the laser welder is extremely strong. It can be applied to various types of aluminum alloys and materials of different thicknesses. Whether it is precise electronic components or large automotive parts, it can handle them with ease. This flexibility makes laser welding an ideal comprehensive solution in aluminum material processing.

- Minimal Post-Processing

Laser welding can produce clean and precise welds, so the subsequent processing requires very little work. The welds usually do not need to be extensively polished or repaired to remain smooth, which not only saves time but also reduces labor costs. At the same time, the lower heat input can reduce the risk of deformation and better maintain the integrity of aluminum components.

How Dynalasers Laser Welders Excel at Aluminum Welding

Dynalasers laser welding company has outstanding performance in aluminum material laser welding. Their equipment is designed to fully address the unique challenges of aluminum welding and can effectively solve common problems. As a result, their fiber laser welders have become the ideal choice for precise aluminum welding in the global market.

- Advanced Aluminum Welding Technology

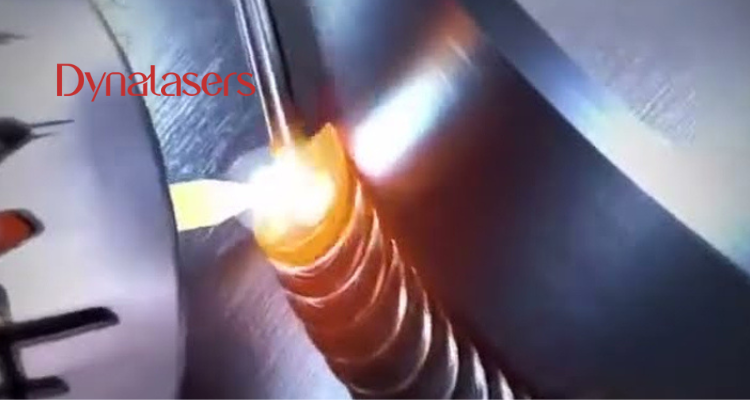

Dynalasers welders employ cutting-edge fiber laser technology, capable of generating stable and high-quality beams. It is highly suitable for dealing with the high reflectivity and high thermal conductivity of aluminum materials. With this technology, common issues such as pores and cracks during welding can be effectively reduced, ensuring that the welds are always clean and strong.

- Optimized Settings for Aluminum Alloys

Each Dynalasers equipment is equipped with pre-set and optimized welding parameters, which have been specifically adjusted for different types of aluminum alloys. As a result, operators do not need to repeatedly test, and can complete the setup more quickly. Whether it is thin plates or thicker components, the equipment can maintain welding quality by flexibly adjusting power and speed, while reducing the occurrence of defects.

- Automation compatibility enhances efficiency

Dynalasers are specifically designed to seamlessly integrate with CNC systems and automated production lines. This compatibility not only significantly boosts production efficiency but also ensures consistent welding quality. For industries such as automotive and aerospace, which have extremely high requirements for aluminum welding, this advantage is particularly crucial.

Best Practices for Laser Welding Aluminum

Laser welding aluminum requires careful attention to several factors to get strong, clean welds. Here are the key steps to follow when using an aluminum laser welding machine.

1. Surface Preparation for Aluminum Laser Welding

Clean the surface thoroughly before welding. Aluminum’s oxide layer can interfere with weld quality, so:

- Use the appropriate solvent to remove dirt, oil stains and grease from the surface.

- Clean mechanically, such as with a steel brush or grinding, to remove the oxide layer on the aluminum surface.

- Ensure that the surface is completely dry, clean and free of any remaining impurities before welding.

2. Shielding Gas for Aluminum Laser Welding

Using the right shielding gas protects the weld pool from oxidation and contamination:

- Argon gas is the most common shielding gas used in aluminum material laser welding.

- In some cases, the combined use of argon and helium can increase the heat input, making the weld seam deeper and stronger.

- Regardless of which gas is used, it is necessary to maintain a stable gas flow and ensure that the weld area is fully covered to avoid the formation of pores.

3. Joint Fit-Up for Precision Welding Aluminum

Good joint fit-up is crucial for laser welding aluminum alloys because the laser beam has a small spot size:

- Before welding, the joint gap must be controlled properly to avoid defects.

- The parts must be aligned precisely so as to ensure uniform heat distribution.

- It is best to use fixtures or clamps to fix the workpiece during welding to maintain stability and prevent displacement during the welding process.

4. Parameter Optimization for Aluminum Laser Welding

Adjusting your laser welder’s settings is essential to handle aluminum’s unique properties:

- To achieve a balance between laser power and welding speed, it is necessary to ensure adequate penetration while avoiding overheating of the material.

- If using pulsed laser, it is important to control the pulse duration and frequency to prevent the formation of cracks.

- In addition, different focusing positions can be tried to find the optimal weld shape and minimize pores.

Following these operational guidelines can help you achieve high-quality and reliable aluminum welding parts when using the laser welding machine.

Comparing Laser Welding to Traditional Methods for Aluminum

During the aluminum welding process, the choice of welding method directly affects the welding speed, quality and overall cost. Now let’s compare the laser welding with the traditional MIG and TIG welding methods, and discuss their respective advantages and disadvantages.

| Factor | Laser Welding | MIG/TIG Welding |

| Speed | Much faster; focused laser melts aluminum quickly for rapid production without losing control | Slower; relies on manual skill and slower heat input, which can delay high-volume projects |

| Quality | High precision and clean welds with minimal distortion; ideal for heat-sensitive aluminum | Strong welds possible but often require more cleanup; higher risk of warping or porosity if not done carefully |

| Cost | Higher upfront cost, but saves money long-term due to faster welding, less post-processing, and reduced material waste | Lower initial cost, but can be more expensive over time due to slower cycle times and extra labor |

Use Case

- Laser welding is ideal for precision parts, thin aluminum sheets, and high-volume manufacturing like aerospace or automotive components.

- MIG welding works well for thicker aluminum and general repairs but may struggle with fine detail.

- TIG welding is great for small, delicate jobs needing strong, clean welds but is slower and requires more skill.

In some cases, laser welding of aluminum is faster, cleaner and usually more cost-effective than traditional MIG and TIG processes.

Understanding Aluminum Welding Challenges

Due to the physical properties of aluminium, it is not easy to obtain a strong, smooth and defect-free weld. Let’s take a look at the challenges faced by welding aluminum materials.

- High Reflectivity

Aluminum can reflect a large amount of laser energy. This high reflectivity may reduce the welding efficiency. If the laser parameters are not adjusted properly, it may also lead to unstable weld quality. Therefore, it is necessary to use the correct laser parameters.

- High Thermal Conductivity

Aluminum has excellent thermal conductivity, which may result in incomplete fusion or weak joints, and it is difficult to form a stable molten pool in the weld seam.

- Oxide Layer

The melting point of the oxide film on the aluminum surface is much higher than that of the aluminum itself. Therefore, it is difficult for the laser to penetrate through it, resulting in insufficiently strong welding and prone to welding defects. If not removed or managed, the oxide layer can cause weld defects.

- Porosity and Cracking

When welding aluminum materials, pores and cracks are prone to occur in the weld seams. Pores will weaken the strength of the weld, while cracks may break under stress. These problems are usually caused by improper selection of the shielding gas, contamination of the material surface, or incorrect laser settings.

Understanding these challenges is the first step to successful aluminum laser welding. The right equipment and technique help overcome these hurdles for strong, reliable welds.

Conclusion

Laser welding is the ideal solution for aluminum, offering precision, strength, and speed where traditional methods fall short. With innovative cooling systems and patented welding tools, Dynalasers handheld laser welding machines ensure consistent performance and high-quality results, making them the trusted choice for modern aluminum welding needs. Contact Dynalasers today to find the right laser welder for your business.

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)