When running a loading bay, you need the right tools to ensure smooth operations. It’s vital to equip your site properly, otherwise you risk limiting productivity and making unnecessary compromises to health and safety. If you want your site to run as smoothly and consistently as possible, your loading bay equipment suite needs to encompass dynamic, flexible tools and machinery, as well as more permanent installations, along with some pieces that fall somewhere in between.

This article will explore the differences between manual, modular equipment and more permanent loading bay installations. It should give you a comprehensive picture of what you need to maximise your output while keeping people safe at work.

Permanent loading bay installations

Getting those big-ticket commercial loading bay equipment installations in place will give your bay the necessary infrastructure it needs to function at its best in the long term. It’s important to account for these in terms of layout and potential structural alterations.

- Dock leveller pits. Your docks need pits for levellers to sit in comfortably, which means digging and concrete work. These pits often require planning permission.

- Loading bay doors. High-speed, roller shutter and sectional overhead doors designed for frequent, heavy-duty use. They need to be well-insulated with easy, secure controls to save energy and guarantee security.

- Dock houses, shelters & seals. The variations of these all offer similar benefits, being designed primarily to provide weatherproofing and shelter security. They can either be built from the inside out, inflatable systems or attached externally.

These are some of the most common and essential installations that loading bay operators should invest in when crafting their equipment suite. It’s also worth remembering that permanent installations can also take much smaller forms, in terms of safety accessories.

- Dock bumpers to absorb vehicle impact

- Wheel guides to align trucks

- Traffic lights and dock lights for safety and visibility

- Safety barriers and chains for a safe separation between vehicles and staff

These are small, but crucial additions to any high-functioning warehouse space.

Essential loading bay equipment

When it comes to more flexible, manually operated and movable equipment, it’s similarly important to build a well-stocked arsenal. There’s no use in establishing a strong infrastructure of installations and structures if you don’t have the right tools to make the most of it.

- Dock boards & plates. These are lightweight, yet very strong solutions to build small, short-term bridges between vehicles and loading surfaces.

- Pallet trucks. Manual moving tools that allow you to lift and shift heavy pallets on foot.

- Forklifts. Vehicles that can lift and move loads that are too heavy or awkward for tackling with a pallet truck. Operators must be trained and licensed.

- Roll cages & containers. These are large container cages that are used to house and move high stacks of goods.

These are the pieces of equipment that keep you nimble and mobile in your loading bay, as well as a broader warehouse space.

Semi-permanent installations/equipment

Beyond major installations and easily flexible pieces of equipment, some items can vary between permanent installation and modular flexibility, such as:

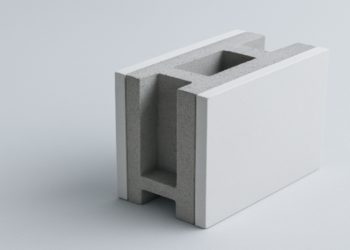

- Dock levellers. Some, often manual models are modular and temporarily locked into loading bays, while telescopic and mechanical bridges are often installed more permanently.

- Scissor lifts. Sometimes, scissor lifts can be operated on wheels to help with loading and picking tasks. Some companies will install permanent hydraulic lifts to help with loading tasks involving higher levels and double-deck trailers.

Understanding the balance between permanent installations and flexible pieces of equipment is vital to running a good loading bay. It might take some shopping around at different suppliers, but picking quality suppliers and installers across the board should always be your MO.

David Prior

David Prior is the editor of Today News, responsible for the overall editorial strategy. He is an NCTJ-qualified journalist with over 20 years’ experience, and is also editor of the award-winning hyperlocal news title Altrincham Today. His LinkedIn profile is here.