Pressure measurement is fundamental in the valve industry and numerous other industrial applications. Among the common terms encountered are PSI and PSIG, which are often used interchangeably but have distinct meanings. Understanding their differences is critical for valve manufacturers who rely on precise pressure measurements to design and produce reliable, safe, and efficient valve systems.

What is PSI?

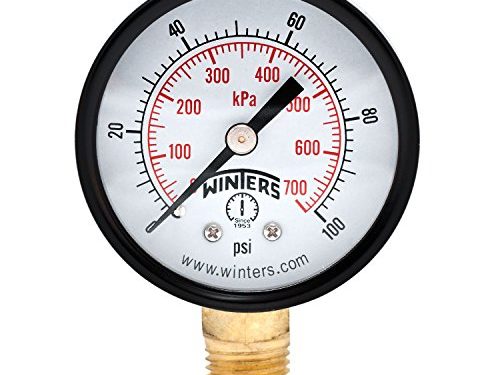

PSI stands for Pounds per Square Inch, and it is a standard unit of pressure used in many industries to quantify force. Essentially, PSI measures the force of one pound exerted over an area of one square inch. This unit is commonly used to describe the pressure within various systems, such as air compressors, hydraulic systems, and even in consumer applications like measuring tire pressure. It is a relative measure of pressure, often expressed as absolute pressure, meaning it accounts for the total pressure, including both the force exerted by a gas or liquid and the atmospheric pressure surrounding the system.

The unit of PSI is particularly useful in fields like valve, engineering, automotive, and plumbing, where precise measurements of pressure are critical for the safety and efficiency of systems. In such applications, PSI helps to ensure that equipment operates within the recommended pressure range, which can vary depending on the specific system requirements. For instance, in a steam system, valves are designed to operate within specific PSI ranges to maintain safe pressure levels. If the internal pressure exceeds the rated PSI, valves like pressure relief valves will activate to prevent damage.

While PSI is used globally, it is more commonly found in the United States and other countries that follow the imperial measurement system. In contrast, many other nations rely on the metric system, where pressure is measured in Pascals (Pa). Despite these differences in measurement systems, PSI remains a critical unit of measurement, particularly in industries that deal with pressurized systems.

What is PSIG?

PSIG, which stands for Pounds per Square Inch Gauge, is a unit of pressure that measures how much pressure exists in a system relative to the surrounding atmospheric pressure. In simpler terms, PSIG indicates the pressure inside a container or system that exceeds the pressure of the air around it.

The concept behind PSIG is based on the idea that atmospheric pressure acts as a baseline. At sea level, the atmosphere exerts a pressure of approximately 14.7 psi. A gauge that reads PSIG measures pressure above this baseline, ignoring the effect of atmospheric pressure. For example, a reading of 0 PSIG indicates that the system’s pressure is equal to the atmospheric pressure. If the system’s internal pressure is higher than the atmospheric pressure, the PSIG reading will be positive, indicating the excess pressure.

PSIG is commonly used in various industries, such as refrigeration, air conditioning, and automotive applications. In these fields, it is important to measure pressure relative to the surrounding atmosphere to assess the functioning of systems, such as tire pressure or HVAC units. This unit allows professionals to easily monitor and adjust pressures without factoring in fluctuations in atmospheric conditions.

Unlike absolute pressure, which includes atmospheric pressure in its measurement (often denoted as PSIA), PSIG only reflects the pressure within the system, which is useful for everyday practical applications where only the pressure above atmospheric levels is relevant.

Key Differences Between PSI and PSIG

PSI (pounds per square inch) and PSIG (pounds per square inch gauge) are both common units used to measure pressure, but they have distinct differences based on the reference point from which the pressure is measured. Understanding these differences is crucial for accurate pressure measurement and effective operation of systems that rely on pressure data.

Reference Point:

- PSI measures absolute pressure. This means it considers the total pressure acting on a surface, including both the pressure from the system and the atmospheric pressure. The reference point for PSI is a perfect vacuum (zero pressure).

- PSIG measures gauge pressure, which is the pressure relative to atmospheric pressure. It excludes the effect of the surrounding atmospheric pressure, meaning it only accounts for the pressure difference between the system and the external environment.

Measurement Context:

- PSI is used in contexts where it’s necessary to know the total pressure, including the atmospheric component. For instance, scientific experiments, thermodynamics, and certain industrial applications, where absolute pressure is critical, rely on PSI.

- PSIG, on the other hand, is more commonly used in practical, everyday applications like tire pressure, air compressors, and HVAC systems. These systems often need to know how much pressure exists above the atmospheric pressure to ensure proper functioning.

Usage in Valves:

- In the valve industry, PSI is often used to define the pressure rating of a valve’s body, indicating the maximum pressure the valve can withstand before leakage occurs. This is essential for ensuring the durability and safety of valves under different operating conditions.

- PSIG is typically used when measuring the pressure within a system, such as pipelines or tanks, where the gauge pressure relative to the outside environment is more critical. For instance, in compressed air systems, PSIG gauges are used to monitor the pressure inside pipes compared to the external atmospheric pressure.

How to Convert PSIG to PSI

Converting between PSIG (Pounds per Square Inch Gauge) and PSI (Pounds per Square Inch) is straightforward once you understand their relationship. The key difference between these two units of measurement lies in their reference points.

- PSIG measures pressure relative to the atmospheric pressure surrounding the object or environment. This means PSIG excludes the influence of atmospheric pressure, effectively setting it to zero at sea level.

- PSI, on the other hand, can be used to describe absolute pressure. This includes both the atmospheric pressure and the pressure within the system, thus providing a measurement that reflects the total pressure exerted.

To convert PSIG to PSI, you simply need to add the atmospheric pressure to the PSIG value. The standard atmospheric pressure at sea level is approximately 14.7 PSI. This value can vary slightly depending on altitude or weather conditions, but for most applications, 14.7 PSI is typically used as the reference.

For example:

- If a system reads 50 PSI, the PSIG is 50 – 14.7 = 35.3 PSIG.

- If a system reads 30 PSIG, the PSI value would be 30 + 14.7 = 44.7 PSI.

This simple conversion allows for accurate pressure measurements, depending on whether you’re concerned with the absolute pressure (PSI) or the pressure relative to atmospheric conditions (PSIG).

Applications in the Valve Industry

PSI and Valve Testing

In the valve industry, precise pressure measurement is essential for ensuring the safety and efficiency of systems. PSI (pounds per square inch) is commonly used in valve testing to determine the overall pressure exerted by fluids within pipes or tanks, accounting for both the internal pressure and the atmospheric pressure. This absolute measurement ensures that valves are designed and tested to handle the correct pressure levels during normal operation, including during pressure tests for leak detection and structural integrity.

Valve testing using PSI is particularly important in industries like oil and gas, where equipment is subjected to extreme pressure conditions. Accurate PSI measurements allow manufacturers to verify that the valves can maintain safe pressure limits, preventing failures that could lead to catastrophic accidents. This form of testing ensures that the materials, sealing mechanisms, and design of the valves meet industry standards.

PSIG in Pipeline Operations

In pipeline operations, PSIG (pounds per square inch gauge) is frequently used to measure the pressure within the system, as it gauges the pressure differential between the pipeline’s internal environment and the surrounding atmospheric pressure. This type of measurement is more practical for everyday operations, as it focuses on the pressure inside the pipeline relative to the atmospheric pressure outside it.

PSIG is particularly useful in applications where maintaining a certain level of pressure above atmospheric conditions is necessary for the fluid to flow effectively, such as in the transportation of gas, oil, or water. By monitoring PSIG, operators can ensure the pipeline is operating under optimal conditions without exceeding pressure limits that could cause leaks, bursts, or valve failures. Proper PSIG monitoring in pipeline systems also helps with leak detection, maintenance scheduling, and energy efficiency, reducing the risk of accidents and minimizing downtime.

Conclusion

Understanding the distinction between PSI and PSIG is not just a technical detail but a practical necessity in the valve industry and beyond. Accurate pressure measurements ensure operational efficiency, safety, and cost-effectiveness. By grasping these concepts, professionals or valve manufacturers can make informed decisions and avoid costly mistakes in their projects.

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)