The prefabricated building business is the fastest-expanding business because developers need fewer building projects, predictable costs, and homogeneous projects. As this segment increases, the producers of modular frames, panels, and structural components are reconsidering the process of metal joining performed in factories, as well as in the satellite production centers. Trends in recent adoptions are pointing to the fact that the compact laser systems are taking this transition, where Xlaserlab X1 Pro is being heard in offering industrial precision in the flexible production environment.

Prefabrication is based on reproducibility and critical limits. The rate of assembling and structural integrity in the long term will be affected because the quality of the weld might be compromised. In order to fulfil these demands, manufacturers are turning to the use of fiber laser technology to fulfil the demands since laser welding has controlled the amount of heat to be applied, produces accurate seams, and uniformity in high production quantities. This move is reflective of bigger changes in the production of construction, whereby greater quantities of accurate machinery are allegedly capable of creating large volumes without the need for expanding factory spaces.

Prefabricated buildings are established on a standardized architecture that is fabricated within standardized circumstances and sent to be constructed. The wall modules and support elements, the connection bracket, and the steel frame must be made to adhere to rigid dimensional provisions to ensure that they are compatible in the field. The traditional welding processes, despite the fact that they are good on their own, can produce distortion and require finishing processes that slow down production.

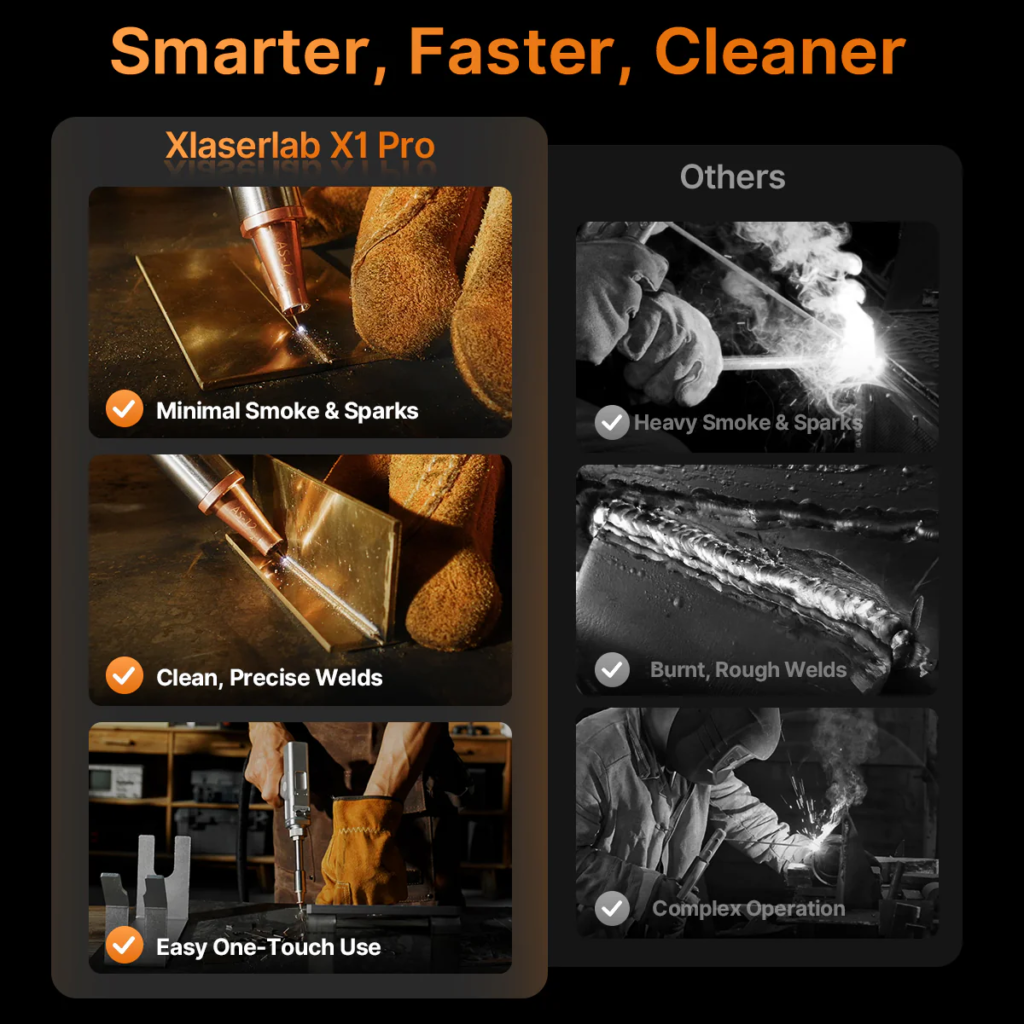

The fiber laser welder can enable manufacturers to carry out such processes with ease. Laser welding can provide precision in placing energy to the joint, reducing areas of heat damage and preserving material geometry. This is particularly important on the thin-gauge steel and mixed-metal assemblies that are primarily used in the modular construction systems. This guarantees that the factories reduce the level of rework and the accuracy of the assembly at the downstream is increased through a consistent weld profile.

The X1 Pro is an all-in-one welding, cutting, and surface cleaning machine, compatible with centralized lines as well as auxiliary workstations. This versatility with prefabrication plants applies to a broad assortment of tasks, such as frame reinforcement, connector fabrication, and corrective adjustments, with no parts that have to be moved among machines. It is also because of the compact fiber laser system that manufacturers can rearrange layouts as the volume of production changes.

Automation facilities also help in prefabricated workflows. The consistency is provided by automated calibration and the stability of the beam output, which will result in the quality of the weld being the same among shifts and operators. This repeatability is significant in modular construction, where the parts can be produced weeks apart, but have to work onsite. The manufacturers who transitioned to the use of a fiber laser welder have a reduced, cumbersome quality control cycle, and the final assembly process has had fewer alignment problems.

On-site Flexibility and Manufacturing Productivity Become Important

Location modifications are mostly unavoidable, but the majority of the prefabricated components are prepared in factories. The installations might require the replacement of metal elements due to the transport constraints, location considerations, or design alterations. Such scenarios are also being considered using portable laser systems, as they can be used to bring accuracy even without installing huge equipment.

The X1 Pro is mobile, a nd it may enable prefabrication teams to move controlled welding work off the factory floor. Trimming or cleaning is possible on-site using the same fiber laser standards used during the manufacturing process. The continuity will be applied to provide quality in the project lifecycle, i.e., production to installation.

Such circumstances are especially good in terms of little heat input. The laser welding also minimizes the possibility of warping of pre-aligned components, and this eliminates the possibility of making corrections during the assembly process. Clean welds also contribute to visual consistency, as an increasing number of elements of modern architecture are also brought out to the open air. A fiber laser welder supports these aesthetic and structural requirements.

The demands of the manufacturers regarding equipment suppliers are also changing with the increase in the use of prefabricated constructions within the world. There is pressure mounting on tools with a tradeoff of industrial performance and flexibility. According to one spokesperson in Xlaserlab, the prefabrication clients are considering systems that do not put them in an inflexible model, as that will enable them to construct high-volume production. The X1 Pro is specially designed to be flexible to ensure that the manufacturer can scale up the operations without affecting the quality of the weld.

This change is also being felt by the workforce. Laser systems have reduced the need for highly specialized manual processes, and qualified personnel can achieve a repeatable result with low learning curves. Such adaptability may be applied in prefabrication environments, where staff demands vary with the pipelines of activity, so the production planning is not volatile. Such integration of a fiber laser welder into these settings is an indicator of the emphasis on the reliability of the processes rather than a method.

The technology that has facilitated design innovation is the introduction of fiber laser technology in the industry. In the effort to benefit from accurate welding, architects and engineers are considering making buildings lighter, with complicated joint geometry, and using mixed media. These designs can be readily achieved more easily and at scale using the processes of laser, and the value of high-tech manufacturing devices in construction today is supported by laser.

Long-term Implications of Modular Construction

The way buildings are designed and made can be potentially altered because of the introduction of laser welding in the prefabrication processes. There is a chance to experiment with new types of modularity and types of assembly methods, with manufacturers becoming more convinced that the methods of joining are repeatable and of high quality. Such a change allows the developers and the contractors to deliver the project quickly and predict the results.

The interoperability between suppliers can also be improved through the use of standardized laser-welded components in a supplier chain. Tolerances also simplify the fitting, as well as reducing logistics, especially in large projects, which have multiple production facilities. Access to a reliable fiber laser welder across the plants helps in balancing the quality levels and reducing the variation.

The increasing use of fiber laser welding in prefabricated building systems has underscored a wider trend in favor of precision-based manufacturing construction. With the rise of modular demands, technologies that promote precision, efficiency, and flexibility will most probably influence the upcoming stage of expansion in the industry.

About Xlaserlab

Xlaserlab is a multinational company that produces high-technology laser machines to carry out welding, cutting, and cleaning processes of surfaces. The company creates small, multi-purpose systems that are meant to aid temporary manufacturing and fabrication settings. The X1 Pro is a combination of a high-performance fiber laser that includes the welding, cutting, and cleaning of materials in a portable format to be used in the factory and on-site. The solutions of Xlaserlab are used in most of the industrial manufacturing, production of components in the industrial manufacturing sector, maintenance, and repair sectors.

Media Contact:

Xlaserlab

Website: www.xlaserlab.com

Email: info@xlaserlab.com

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)