Introduction

UK manufacturing faces rising costs, global competition, and pressure to meet high-quality standards, often leading to production delays and safety risks in sectors like aerospace and automotive. Traditional manufacturing methods struggle with inconsistent tolerances, which undermine cost-effectiveness and sustainability. By integrating aerospace CNC machining tolerances, manufacturers can achieve precision,and improve operational efficiency.

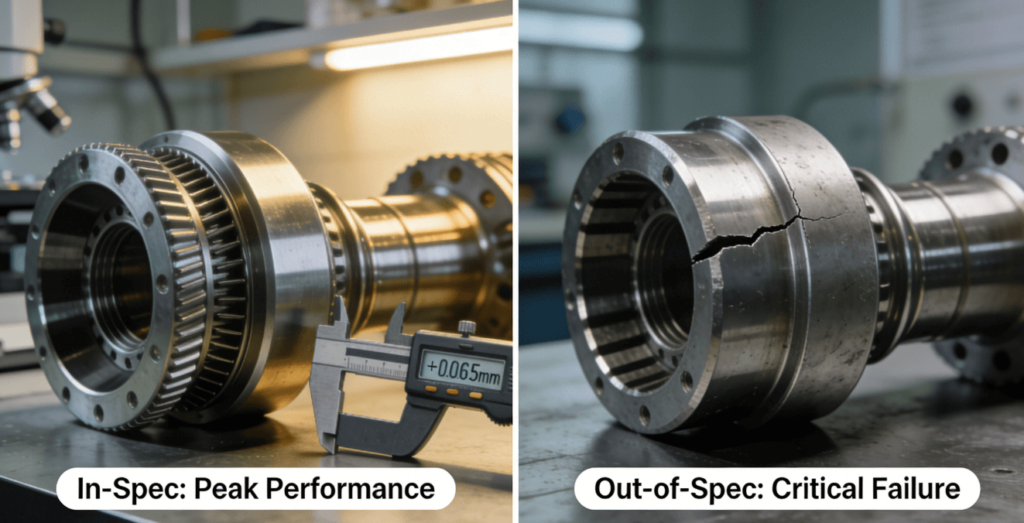

Figure 2: Visual explanation of how machining tolerance directly impacts performance and safety. Tight tolerances (left) prevent catastrophic failures (right).

Why Are Precision Tolerances Essential for UK Manufacturing Competitiveness?

The competitiveness of UK Manufacturing hinges on its ability to move beyond traditional production methods and embrace world-class Precision Engineering. In an era of globalised supply chains and intense cost pressure, the ability to consistently produce high-value, reliable components is a key differentiator. Understanding how machining tolerance affects performance is at the heart of this transformation. The following points detail why mastering precision tolerances is non-negotiable for maintaining a competitive edge.

Mitigating Operational Costs and Enhancing Efficiency

Precision tolerances directly impact the bottom line for UK Manufacturing by minimizing assembly delays, scrap rates, and rework. Adhering to tighter tolerances fosters a ‘right first time’ culture, significantly reducing waste especially with costly alloys and optimizing labour and machine time. This enhances cost efficiency and competitive value .

Ensuring Product Performance and Reliability in High-Stakes Sectors

In high-value sectors like aerospace and automotive, component failure is unacceptable. Precisely calculated tolerances are essential, ensuring proper fit, function, and longevity to prevent issues like premature wear. Adhering to these specifications guarantees optimal performance and builds the reputation for quality that UK Manufacturing requires to compete in global markets.

Adherence to International Standards for Market Access

Achieving and demonstrating precision requires a framework of quality, which is provided by international standards.

- The Role of ISO 9001 and Similar Standards

For UK Manufacturing, certifications like ISO 9001 are essential. They provide a verified framework for consistent quality management, ensuring machining tolerances are reliably met and building crucial trust with global clients.

- A Practical Example: From Leakage to Reliability

A hydraulic valve at tolerance limits may leak. By applying tighter, aerospace-level controls, UK Manufacturing firms can eliminate such failures, enhancing product reliability and reducing warranty costs significantly.

How Do Aerospace CNC Machining Standards Enhance Cost-Effective Production?

Aerospace manufacturing is synonymous with uncompromising quality and safety. The CNC tolerance standards for aerospace, such as the AS9100 series governed by the International Aerospace Quality Group (IAQG), are designed to ensure extreme reliability. While these standards may seem stringent, their implementation is a powerful driver for cost-effective production. The rigorous protocols inherent in Aerospace CNC Machining force a paradigm shift from reactive correction to proactive prevention. By mandating detailed documentation, first article inspection (FAI), and statistical process control (SPC), these standards identify potential deviations long before they result in large-scale production errors.The path to 25% cost savings is achieved through several key mechanisms.

Optimized Aerospace CNC machining tolerances minimize material waste by producing parts closer to net shape . This precision reduces rework and scrap, lowering labor and machine costs. Enhanced final product reliability also decreases warranty claims, ensuring long-term savings and protecting manufacturer reputation .

What Role Does Sustainable Manufacturing Play in Precision Engineering?

The integration of Sustainable Manufacturing principles is no longer optional for modern industry; it is a core component of a competitive strategy. For UK Manufacturing, this is particularly relevant in high-value sectors like aerospace, where precision machining for aircraft parts is critical. The relationship between precision engineering and sustainability is synergistic, creating a powerful combination that drives both environmental and economic benefits. This section explores this vital connection through three key aspects.

Minimising Material Waste Through Resource Efficiency

At the heart of sustainable practice is the efficient use of resources, and this is where precision machining for aircraft parts delivers significant impact. High-precision CNC technology is fundamentally designed to minimise material scrap. By achieving exceptionally tight tolerances and optimised tool paths, the amount of raw material removed as waste is drastically reduced. For example, when producing a turbine blade from an expensive titanium billet, advanced precision machining techniques ensure that a far greater percentage of the original material is transformed into the final, high-value component. This direct reduction in waste not only lowers material costs but also decreases the environmental burden associated with material extraction, transportation.

Reducing Energy Consumption and Carbon Footprint

Beyond material savings, Sustainable Manufacturing encompasses energy efficiency, an area where modern precision engineering excels. Contemporary CNC machines are engineered for lower power consumption, featuring energy-saving modes and efficient drive systems. Furthermore, the very nature of high-precision manufacturing contributes to energy reduction. Optimised machining strategies, such as high-speed machining and reduced cycle times, lower the energy required per part. This focus on operational efficiency aligns with broader environmental guidelines, such as those promoted by the U.S. Environmental Protection Agency (EPA), which encourages industries to adopt cleaner production techniques. By investing in advanced precision machining technology, manufacturers can simultaneously enhance their productivity and reduce their carbon footprint, a crucial step for UK Manufacturing in meeting both corporate and national sustainability targets.

Ensuring Compliance and Market Advantage Through Standards

Adherence to international standards provides a framework for systematically managing environmental responsibilities, turning compliance into a competitive advantage.

- The Framework of ISO 14001 and Regulatory Alignment

For UK Manufacturing, obtaining certifications like ISO 14001 is crucial. This standard provides a systematic framework, often aligned with the PDCA cycle (Plan-Do-Check-Act), to continuously enhance environmental performance in areas like energy use and waste management . It ensures manufacturers not only comply with tightening regulations but also proactively integrate Sustainable Manufacturing into core operations .

- Building Brand Reputation and Meeting Market Demands

Demonstrating a commitment to Sustainable Manufacturing, such as through ISO 14001 certification, significantly enhances a company’s brand reputation. It sends a strong, positive signal to clients, investors, and regulators about the seriousness of its environmental stewardship. This market differentiation is vital for securing contracts within environmentally conscious supply chains, particularly in high-value sectors like aerospace, providing Manufacturing with a critical competitive advantage by building trust and aligning with market expectations .

How Can UK Manufacturers Implement High-Precision CNC Aerospace Solutions?

Adopting high precision CNC aerospace methodologies requires a strategic and phased approach. The first step involves a thorough evaluation of current capabilities against the stringent aerospace part machining guidelines. This includes assessing existing machinery, metrology equipment, and workforce skills. Investing in modern 5-axis CNC technology is often essential, as it allows for complex geometries to be machined in a single setup, thereby improving accuracy and reducing cumulative errors. Selecting the right materials is equally critical; aerospace-grade aluminium, titanium, and high-performance alloys demand specific tooling and machining parameters to maintain tolerance integrity.

Effective implementation also hinges on robust quality management systems. Achieving AS9100 certification provides a structured framework for controlling every aspect of production, from design and sourcing to manufacturing and inspection. For many UK Manufacturing firms, partnering with an experienced provider can accelerate this transition. Specialized CNC machining services that already possess the necessary certifications and expertise can serve as valuable extensions of a company’s production capacity.

H2-5: What Are the Safety Benefits of Tight Tolerance Machining in Industrial Applications?

The imperative for tight tolerance machining safety is most apparent in industries where component failure can have catastrophic consequences. In Industrial Technology applications, from aerospace engines to medical devices, the relationship between how machining tolerance affects performance is fundamentally a safety issue. Tolerances are engineered to ensure that parts can withstand operational stresses, thermal expansion, and dynamic loads without compromising the system’s integrity.

Consistent tolerances ensure proper sealing in fluid systems, preventing leaks of hazardous materials, avoiding short circuits. In medical devices, tight tolerances are critical for biocompatibility and reliable operation during surgical procedures. To achieve this level of reliability, manufacturers must rely on stringent quality control. Suppliers such as LS Manufacturing utilize certified processes and advanced inspection technologies like Coordinate Measuring Machines (CMMs) to verify that every part meets the specified safety-critical dimensions. This rigorous approach to tight tolerance machining is what enables Industrial Technology sectors to innovate safely and reliably, protecting both end-users and brand reputation.

Conclusion

The integration of these high-precision methodologies is no longer a luxury for niche industries but a fundamental requirement for maintaining competitiveness in a global market. By embracing these advanced practices, UK manufacturers can secure a leading position in high-value engineering sectors.

For a free consultation on implementing these solutions, visit our service page to get an instant quote.

Author Biography

John Doe is a precision manufacturing expert with over 10 years of experience in aerospace CNC machining and industrial technology. He specializes in helping manufacturers optimize processes for efficiency and compliance.

FAQs

Q1:What are the key CNC tolerance standards for aerospace?

A:Aerospace standards like AS9100 ensure parts meet rigorous safety and performance requirements, with tolerances as tight as ±0.005mm to prevent failures in extreme conditions.

Q2:How can precision machining reduce costs in UK manufacturing?

A:By minimizing material waste and rework through high-precision CNC processes, manufacturers can achieve up to 25% cost savings while maintaining quality.

Q3:What certifications are critical for aerospace part machining?

A:ISO 9001, AS9100, and ISO 14001 certifications are essential, ensuring adherence to quality, environmental, and aerospace-specific standards for reliability.

Q4:How does machining tolerance affect product performance?

A:Tight tolerances prevent issues like leakage or vibration in components, directly enhancing efficiency, safety, and longevity in applications like aerospace.

Q5:Can sustainable practices be integrated with precision engineering?

A:Yes, through methods like energy-efficient CNC machining and waste reduction, sustainable manufacturing complements precision engineering for eco-friendly outcomes.