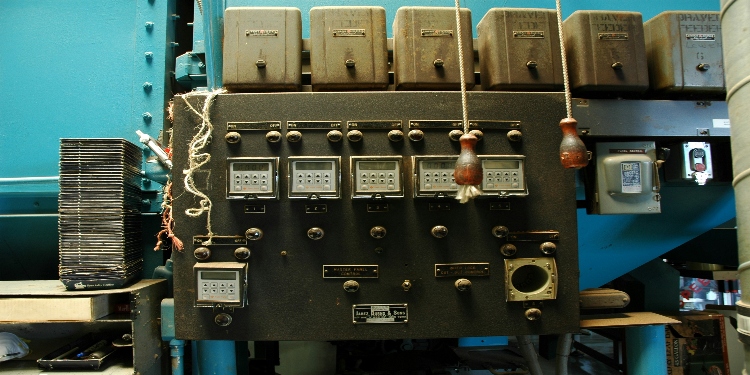

In modern power systems, electrical panels serve as crucial equipment for power distribution and control, and their manufacturing quality directly impacts the safe and stable operation of the power system. During the electrical panel manufacturing process, the application of CNC busbar machines has become a core element in ensuring product quality and production efficiency. This highly automated specialized equipment, through its precise processing capabilities, is transforming traditional electrical panel manufacturing methods.

What is a CNC busbar machine?

CNC busbar machine is a specialized busbar processing equipment that integrates computer control, precision mechanics, and automation technology. It receives digital information from design drawings through a CNC system, transforms it into specific processing instructions, and controls the actuators to complete precise punching, cutting, and bending of copper or aluminum busbars. The busbar machine mainly consists of a CNC system, transmission mechanism, processing unit, and auxiliary devices. From a technical perspective, firstly, the CNC busbar machine boasts extremely high processing precision. Utilizing servo motor drive and high-precision ball screw transmission, its positioning accuracy reaches ±0.1mm, and its repeatability reaches ±0.05mm. This level of precision ensures the consistency of each processed part, laying the foundation for standardized production of electrical panels. Secondly, the multi-functional busbar punching machine possesses powerful processing capabilities, capable of performing multiple processing steps such as punching, shearing, and bending, achieving multi-purpose functionality. Furthermore, modern CNC busbar machines also feature intelligent characteristics, such as automatic mold changing, online detection, and fault diagnosis, greatly improving the equipment’s automation level.

Application of CNC Busbar Machines in Electrical Panel Manufacturing

CNC busbar machines play multiple important roles in the manufacturing process of electrical panels. Firstly, they are crucial for the precise cutting of busbars. Traditional manual cutting methods are not only inefficient but also lack precision. CNC busbar machines, through precise length and cutting angle control, ensure that each busbar is sized perfectly, facilitating subsequent assembly. Secondly, they are essential for machining various mounting holes. Busbars in electrical panels need to connect to components such as circuit breakers and disconnect switches, and the accuracy of these connection points directly affects the electrical performance of the equipment. CNC busbar machines can precisely machine various specifications of round, square, and irregularly shaped holes, ensuring the positional and dimensional accuracy of the mounting holes. Statistics show that using CNC busbar machines can improve hole machining accuracy by more than 50%. CNC busbar machines also excel in busbar bending. The internal spatial layout of electrical panels is often complex, requiring busbars to undergo multiple bends to adapt to the installation space requirements. CNC busbar bending machine can precisely control the bending angle and direction, enabling the processing of complex shapes and ensuring accurate positioning of the busbar within the electrical panel.

The Role of CNC Busbar Machines in Improving the Quality of Electrical Panels

The application of CNC busbar machines significantly improves the product quality of electrical panels. In terms of electrical performance, precise machining ensures the reliability of busbar connections. Studies show that busbars machined by CNC busbar machines can reduce contact resistance by 20%-30%, directly improving the conductivity of the electrical panel and reducing energy loss. Regarding insulation performance, busbars machined by CNC busbar machines have better surface quality. Smooth cuts and precise dimensional control effectively avoid electric field concentration, improving the insulation level of the product. This advantage is particularly pronounced in high-voltage electrical panels, significantly reducing the risk of partial discharge. Furthermore, CNC busbar machines help improve product consistency. Under traditional machining methods, differences may exist between different batches, and even within the same batch. CNC busbar machines, through digital control, ensure that each machined part fully meets design requirements, which is crucial for guaranteeing the reliability and interchangeability of electrical panels.

The Role of CNC Busbar Machines in Improving Production Efficiency

The role of CNC busbar machines in improving production efficiency is equally significant. First, it automates the processing. Traditional processing methods require multiple people to work together, while CNC busbar machines only require one operator, increasing production efficiency by 3-5 times. This advantage is particularly pronounced in mass production. Second, CNC busbar machines significantly shorten production preparation time. Traditionally, changing product specifications requires readjusting tooling fixtures, which is time-consuming. CNC busbar machines, through program control, can quickly switch production types simply by calling different processing programs, adapting to the modern market’s demand for multi-variety, small-batch production. Furthermore, CNC busbar machines reduce raw material waste. Through optimized layout and precise cutting, material utilization can be increased by 15%-20%. This not only reduces production costs but also aligns with the development concept of green manufacturing. Statistics show that using CNC busbar machines can reduce overall production costs by more than 25%.

The Integration of CNC Busbar Machines with Intelligent Manufacturing

With the development of Industry 4.0, CNC busbar machines are deeply integrating with intelligent manufacturing. Modern CNC busbar machines generally have network communication capabilities and can be connected to the factory’s Manufacturing Execution System (MES). By uploading processing data in real time, transparent management of the production process is achieved. Managers can remotely monitor equipment operation status and understand production progress in a timely manner. The application of intelligent optimization algorithms is another important development direction. Through artificial intelligence technology, CNC busbar machines can automatically optimize processing paths and process parameters. For example, when processing complex-shaped busbars, the system can automatically calculate the most reasonable processing sequence, reducing idle travel time and improving processing efficiency. The application of predictive maintenance technology also greatly improves equipment reliability. By monitoring the operating parameters of key components, the system can predict possible failures and issue maintenance reminders in advance. This proactive maintenance method can effectively reduce equipment downtime and ensure production continuity.

Precautions in Practical Applications

To fully utilize the efficiency of CNC busbar machines, the following key points need attention. First, optimize the processing technology. Different busbar materials require different processing parameters. For example, when processing copper busbars, it is important to control the cutting speed to avoid material sticking to the tool; when processing aluminum busbars, special attention must be paid to chip removal. Reasonable parameter settings can not only ensure processing quality but also extend tool life. Second, maintain and service the equipment. Regularly check the accuracy of the transmission system and replace worn parts promptly; keep the guide rails and lead screws clean and lubricated; calibrate the testing devices regularly. Establishing a sound equipment maintenance system is key to ensuring the long-term stable operation of the equipment. Furthermore, operator training is also crucial. Operators must not only know how to use the equipment but also understand the processing principles and be able to judge processing quality. Regularly organizing technical training and sharing best practices can help operators better utilize the equipment’s performance.

Conclusion

CNC busbar machines play an irreplaceable role in the manufacturing of electric panels. They not only improve product quality and production efficiency but also drive the transformation and upgrading of the electric panel manufacturing industry. With technological advancements, CNC busbar machines will continue to develop towards greater precision, intelligence, and environmental friendliness. For electric panel manufacturers, grasping technological development trends, timely introducing advanced CNC equipment, and optimizing production processes are key to enhancing market competitiveness. In the future, with the in-depth application of intelligent manufacturing technology, CNC busbar machines will undoubtedly play an even more important role in the electric panel manufacturing industry.