Introduction

In today’s competitive manufacturing landscape, companies across aerospace, medical devices, and consumer electronics face a critical challenge: how to control precision part production costs while maintaining uncompromising quality standards and accelerating time-to-market. Traditional cost-reduction approaches often focus solely on material selection or volume pricing, potentially compromising long-term value and performance. However, research indicates that strategic optimization integrating engineering design, advanced technologies, and manufacturing expertise can deliver significant savings while enhancing quality.

This article explores five research-driven strategies that help manufacturers achieve up to 40% cost reduction in CNC machining operations through intelligent design, digital validation, and sustainable practices.

How Can Strategic Tolerance Design Reduce Manufacturing Costs by Up to 40%?

Precision is fundamental to precision machining, but uniformly applying tight tolerances to all features represents one of the most significant cost drivers in component manufacturing.

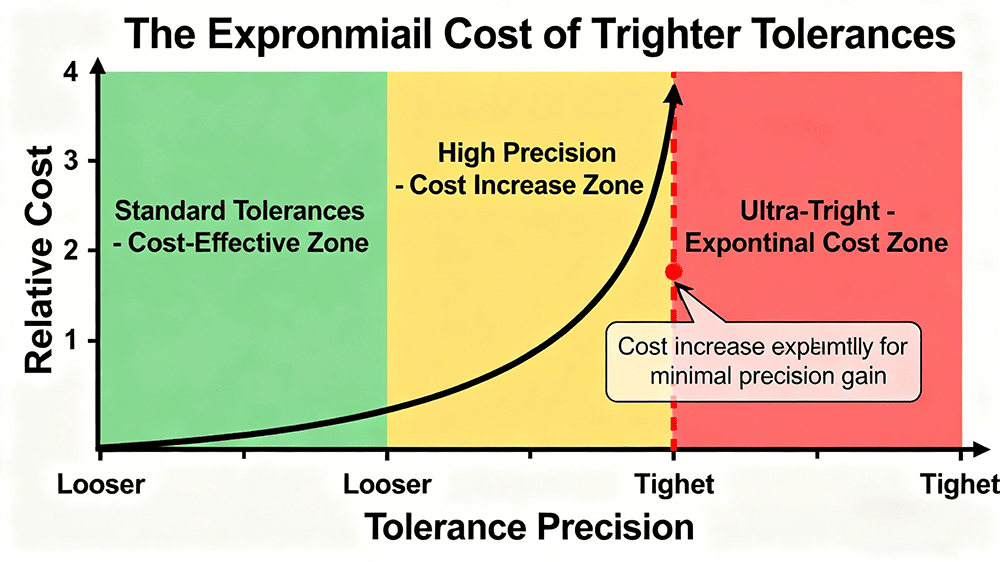

The Exponential Relationship Between Tolerance and Cost

Tightening tolerance requirements increases manufacturing costs exponentially rather than linearly. According to the National Institute of Standards and Technology (NIST) research on measurement science, maintaining ultra-tight tolerances demands more precise equipment, slower machining speeds, additional tool changes, extended inspection times, and higher scrap rates. The cost of exceeding necessary precision often surpasses the raw material value itself.

Implementing Critical Function Analysis

The solution lies in replacing guesswork with a scientific “Critical Function Analysis,” a systematic process requiring close collaboration between design and manufacturing engineers:

- Step 1: Identify Critical Interfaces and Functional Surfaces.Analyze the part’s role within the final assembly to pinpoint which holes, shafts, planes, or surfaces are core to product performance, interchangeability, lifespan, or safety. These features often constitute only 20-30% of all dimensions.

- Step 2: Differentiate Non-Critical Features.Identify structural features, non-mating surfaces, etc., that serve only for weight reduction, aesthetics, or have no substantial impact on overall function.

- Step 3: Develop a Tiered Tolerance Strategy. Assign strict, necessary tolerances to critical functional surfaces; for non-critical features, relax them to standard or economical machining tolerance grades. This approach can significantly reduce machining time, simplify inspection processes, and lower scrap rates. Industry case studies demonstrate the efficacy of this method. For instance, one medical device manufacturer implemented a rigorous tolerance analysis and reported that over 30% of tolerances could be relaxed, which directly contributed to a more competitive CNC machining service quote without compromising functionality. Manufacturers seeking to apply this methodology can find detailed frameworks in technical resources published by industry leaders.

A comprehensive CNC Rapid Prototyping Cost Control Guide: Key Factors and Solutions demonstrates how manufacturers have achieved substantial savings through strategic tolerance design while maintaining part functionality.

Figure 2: Research indicates that specifying unnecessarily tight tolerances is a major cost driver. Strategic tolerance loosening can yield massive savings.

Can Digital Prototyping Eliminate Late-Stage Design Changes and Associated Costs?

Validating designs before full-scale production represents the most effective defense against costly errors, with digital prototyping technologies playing a transformative role in modern manufacturing.

Early Validation Through Rapid Manufacturing

Utilizing 3D printing or rapid CNC machining for functional prototypes enables identification of design flaws, assembly interferences, and performance issues at the earliest possible stage. Research shows that modifying CAD files during prototyping is exponentially cheaper than altering production tooling later. The advantages of rapid prototyping include accelerated iteration cycles that allow design teams to optimize for manufacturability and reliability, significantly reducing failure risks during mass production.

Manufacturers offering integrated online rapid prototyping services facilitate seamless transitions from prototype to production, ensuring knowledge gained during validation directly informs manufacturing strategy. This approach typically delivers 10x or greater return on investment by avoiding expensive engineering change orders (ECOs) during production.

Do Sustainable Manufacturing Practices Unlock Hidden Efficiency Benefits?

While sustainability is often viewed as a compliance cost, modern sustainable manufacturing practices directly correlate with operational excellence and cost efficiency.

Resource Optimization and Waste Reduction

Integrating sustainability into manufacturing drives direct operational efficiency and cost benefits. Optimizing resources and minimizing waste creates an environmental and economic win-win.

- Optimize Tool Paths

- Use advanced CAM software for efficient paths that reduce non-cutting movements.

- Effect:Shortens cycle times, lowers energy use and tool wear.

- Smart Material Nesting

- Apply nesting software to optimize part layout on raw materials.

- Effect:Maximizes yield, reducing material costs and waste fees.

- Implement Recycling

- Segregate and recycle production waste like metal chips and used fluids.

- Effect:Turns waste into revenue streams and cuts disposal costs.

- Systematic Energy Management

- Monitor and improve energy use via frameworks like ISO 14001.

- Effect:Typically achieves over 5% annual energy cost reduction.

Market Access Through Sustainability Commitment

Beyond direct savings, sustainability credentials increasingly influence procurement decisions, with many large corporations and institutions prioritizing partners demonstrating environmental responsibility. This creates competitive advantages in sectors where corporate social responsibility impacts supplier selection.

What Factors Beyond Price Determine True Manufacturing Partner Value?

The lowest quotation doesn’t necessarily translate to the lowest total cost of ownership. Truly valuable manufacturing partners offer capabilities that ensure long-term project success.

Comprehensive Technical Capabilities and Certifications

Partners offering diverse services—precision machining, sheet metal fabrication, injection molding, and surface finishing—can recommend the most appropriate and economical technology for specific project requirements. Equally important are industry-specific certifications like ISO 13485 for medical devices and AS9100D for aerospace, which signal rigorous quality cultures capable of handling complex component manufacturing challenges.

Engineering Collaboration and DFM Expertise

The value of a true manufacturing partner lies in its ability to provide expert Design for Manufacturability (DFM) feedback during early design stages, optimizing designs at their source to avoid cost traps. This is exemplified in the aerospace sector, where a strategic supplier selection process that included a comprehensive DFM analysis service for a critical bracket resulted in design changes that cut machining time by 25%. Such collaborations underscore how early engineering input transforms prototypes into production-ready, cost-effective components. Experts in the field often share insights from these successful partnerships through in-depth articles and white papers. This collaborative approach proves particularly valuable for custom rapid prototyping manufacturing projects where design decisions lock in majority of lifetime costs.

How Do Advanced Manufacturing Technologies Deliver Value Beyond Initial Cost Considerations?

While advanced technologies may carry higher upfront costs, their value in machining complex components often outweighs initial investments through enhanced capabilities and efficiency.

Reduced Lead Times Through Advanced Machining

Technologies like simultaneous 5-axis machining enable completion of complex geometries in single setups, eliminating error accumulation from multiple fixturing operations. This significantly reduces total production time while enhancing accuracy—particularly valuable for components requiring deep cavities, undercuts, or complex contours.

Design Innovation and Consistency

Advanced manufacturing technologies provide engineers greater design freedom, enabling innovative geometries impossible or prohibitively expensive with traditional methods. Single-fixture machining better maintains geometric tolerances, yielding superior performance and reliability in final assemblies—critical for high-demand applications where consistent quality outweighs initial cost considerations.

Conclusion

Optimizing CNC machining costs is a strategic, multi-faceted process that goes beyond simple price comparison. It hinges on the integration of intelligent design, technology adoption, sustainable practices, and strategic partner selection. The research-backed strategies outlined—from strategic tolerance design to digital prototyping and advanced technology adoption—enable manufacturers to significantly enhance efficiency and cost-effectiveness without compromising on quality or innovation.

Ready to apply these strategies to your projects? Contact a manufacturing expert today to get a personalized DFM analysis and a precise quote, and take the first step towards optimized costs and enhanced quality.

FAQs

1. What is the most significant cost driver in CNC machining beyond material selection?

Part geometry complexity, tolerance requirements, and surface finish specifications primarily influence costs. Complex designs require longer programming and machining times, while tight tolerances demand more precise equipment and additional quality control measures.

2. Is CNC machining suitable for low-volume production runs?

Yes, CNC machining requires no tooling, making it ideal for low-volume production and rapid prototyping. For very high volumes, injection molding may become more cost-effective, but CNC offers flexibility for small to medium batches.

3. How can manufacturers ensure parts meet industry regulations and quality standards?

Selecting suppliers with robust quality control systems—including First Article Inspection, in-process checks, and final inspection using coordinate measuring machines (CMMs)—ensures compliance with relevant standards like ISO 13485 (medical) or AS9100D (aerospace).

4. Which factors determine whether aluminum or steel is more cost-effective for a specific application?

Aluminum generally machines faster with less tool wear, reducing costs. However, material selection should prioritize application requirements—steel offers greater strength for high-stress applications, while aluminum provides weight savings where lightness is critical.

5. What ensures smooth transitions from prototyping to mass production?

Choosing manufacturers offering end-to-end services—from rapid prototyping to full-scale production—ensures design data consistency and applies prototyping learnings directly to manufacturing processes, minimizing transition risks and costs.

Author Bio

Leo Tang is a Senior Manufacturing Engineer and a recognized contributor to industry publications on advanced manufacturing techniques. The insights in this article are drawn from years of hands-on experience in applying precision engineering principles to complex challenges across aerospace and medical device sectors. Leo Tang is part of the engineering team at JS Precision, a CNC machining services supplier known for its AS9100D and ISO 13485 certified operations and its commitment to providing actionable DFM analysis service to its partners.

To continue learning about CNC machining cost optimization and tolerance design from industry practitioners, readers are invited to explore the technical blog maintained by their engineering team.

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)