You’re probably surrounded by polymers now — in the plastic case of the device you’re using, the rubber of your sneakers, the adhesives holding your shoes together, the coating on your jacket, in the rubber hose running water in your shower. The key to their unique properties? Long chains of repeating molecular units, or monomers, bound together. That said, the properties of such polymer materials often can be greatly improved by a technique called cross linking in polymers. This article discusses what cross linking is, why it is important, and how cross linking contributes to enhanced polymer performance for a range of applications.

What is Cross Linking in Polymers?

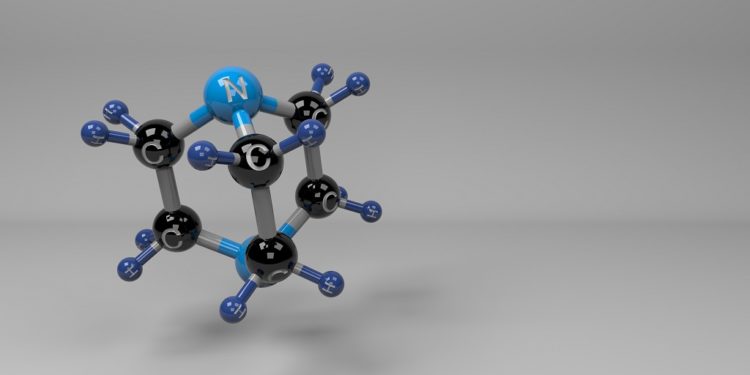

Cross linking in polymers science is the covalent or non-covalent bond structure that forms between polymer chains. Rather than a bunch of little long strings all over the place that can move individually, cross link ties these strings together at several points so that they can’t move very well. This network of interconnected structures alters the physical and chemical properties of the polymer, often imparting greater strength, flexibility, and resistance to heat and chemicals.

The cross links will be covalent bond linking, ionic bond linking or physical bond linking and so on according to the polymer type and cross linking manner. The density and character of these cross links are key factors that determine the final material properties.

How Does Cross Linking in Polymers Work?

The cross inking commonly arises from chemical reactions that are initiated by heat, light, or by the presence of chemical additives. Here are some common methods:

Chemical Crosslinking

Chemical crosslinking provides a presynthesized three-dimensional (3D) scaffold network by the in situ formation of covalent bonds between polymer chains with the aid of chemical crosslinkers (synthetic or biological). For instance, sulfur is added to rubber to vulcanize it, forming cross-links between chains that will impart greater elasticity and resistance to wear.

Radiation Cross Linking

A process in which polymers are exposed to high-energy radiation, such as gamma radiation or electron beams, which cause polymers to develop free radicals, resulting in cross-chain bonding.

Crosslinking by Heating

Many polymers will undergo a reaction at elevated temperatures resulting in the formation of crosslinks in the presence of a catalyst.

The degree of cross linking — or cross link density — is tightly regulated in order to obtain the targeted set of properties.

Influence of Cross linking on Polymer Characteristics

Crosslinking in polymer science often changes the entire set of the material’s properties, including the most fundamental, making it a powerful tool. Some major effects include:

Improved Mechanical Strength

Cross-linked polymers usually have greater tensile strength and toughness. The crosslinked structure limits the mobility of the polymer chains to give higher resistance to deformation and breakage when subjected to stress. This is particularly true for applications such as automotive components, seals and structural parts.

Super Elasticity and Durability

Elastomers (rubber-type materials) are produced with a cross linking structure to provide stretchability of polymer chains with their subsequent return to the original shape. For tires, gaskets and other flexible products, this is a crucial property.

Increased Thermal Stability

Cross linked polymers usually possess a higher melting point and better thermal resistance. The chemical bonds between chains are what prevents the polymer from melting or flowing at higher temperatures; the stronger the bond, the more rigid the solid.

Improved Resistance to Chemicals and Solvents

The cross linked chains constituting the connected network lower the solubility and swelling of the polymer in solvents. This quality makes cross linked materials perfect for such coatings, adhesives and packaging that must withstand exposure to strong chemicals.

Less Creep and Better Dimensional Stability

Cross linked polymers are resistant to long-term deformation (creep) when subjected to a constant load over time. This allows the material to retain its shape and structural integrity for the long life of the system.

Applications Improved by Cross Linking of Polymers

The advantages of cross linking are used in numerous applications and products:

- Rubber and Tires: Vulcanized rubber connected by sulfur cross links is stronger, more pliant, and heat-resistant, all this is very needed for long-lasting tires and many rubber industrial goods.

- Medical Devices: Implants and prosthetics that require strength, compatibility with the body, and durability utilize cross linked hydrogels and polyethylene.

- Electronics: Cross linked polymers are utilized as insulators and protective layers due to their thermal and chemical stability.

- Adhesives and Sealants: Cross linking provides improved resistance to chemicals and better mechanical strength, which makes these polymers the ideal choice for bonding and sealing.

- Packaging: Cross linked polyethylene films are better in terms of puncture resistance and barrier properties.

Determination of Controlled Cross Link Density to Achieve Best Performance

Although cross linking offers many advantages, excessive cross linking can result in loss of flexibility and processability. Cross linking in polymers can harden and crack when struck. On the other hand, too little cross linking may be less than the required strength or thermal resistivity.

Hence, all manufacturers have to optimize the cross linking density according to the application. This compromise is to make the polymers work well and keep them flexible, durable and easy to make.

Difficulties in Cross Linking Polymers

Although the cross link between the polymer chains has many positive qualities, it can be problematic:

- Cross Link Density Management: It is difficult to attain uniform and consistent cross linking across the material without strict control of the reaction conditions and the cross linking agents.

- Processing: Cross linked polymer is usually thermosetting (it will not melt) and as such cannot be recycled (unlike thermoplastics).

- Cost: More steps and materials for cross linking can lead to higher production costs.

Current research efforts are directed toward the design of smarter crosslinking strategies that can be better controlled, are more sustainable, and recyclable.

Future Trends in Cross Linking of Polymers

The scope of potential cross linking grows as further developments in polymer chemistry and material science are made:

- Smart Cross Linked Polymers: Polymers that react to environmental stimuli (temperature, pH, light) by shifting their cross link structure, allowing materials that can heal themselves and behave adaptively.

- Eco-friendly Cross Linking: Using bio-based crosslinkers and greener processes to lower environmental impact.

- Nanotechnology-Enabled Cross Linking: Incorporating nanomaterials to form hybrid network structures with enhanced mechanical and functional properties.

These new technologies yield industrial polymers that have customized properties for the next generation of applications.

Conclusion

Cross linking is a basic process in which simple polymer chains are converted into three-dimensional networks with mechanical, thermal, and chemical properties superior to those of the original material. Knowing how cross linking takes place and how it affects polymer properties allows scientists and engineers to develop materials that satisfy the most exacting demands of contemporary technology and daily life.

Whether in rubber tires, artificial joints, or high-performance coatings, the properties of these cross linked polymers are far better than what an unlinked polymer chain alone could achieve. As research continues, the greater the ability to control and innovate within cross linking, the more versatile and sustainable polymer materials will become in the future.

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-120x86.png)