If there’s ever been a moment of frustration when trying to figure out which wire goes where, electrical wire labels are the unsung heroes of organization and safety. Whether it’s a simple home renovation or a large-scale commercial electrical installation, properly labeled wires can mean the difference between a seamless workflow and a chaotic, time-consuming mess. And let’s be honest—no one enjoys playing the guessing game with a bundle of identical-looking wires.

The Lifeline of Electrical Safety

One of the most significant benefits of wire labels is their ability to enhance safety. Electrical work isn’t something to take lightly, and when dealing with potentially dangerous current-carrying conductors, clarity is everything. Proper labeling allows for quick identification of live wires, neutral wires, and ground wires, drastically reducing the risk of accidental shocks or hazardous mistakes during repairs or upgrades.

Imagine opening up a breaker panel only to find an unmarked jungle of wires. Without clear labels, even experienced electricians would have to spend extra time testing, tracing, and second-guessing. And for homeowners attempting minor electrical work, a lack of proper identification can lead to some very costly—or even dangerous—errors. A well-labeled system prevents confusion, minimizes risks, and ensures that everyone working on an electrical system knows exactly what they’re dealing with at a glance.

Simplifying Circuit Management

Beyond safety, electrical wire labels make circuit management a breeze. In any modern home, office, or industrial setting, multiple circuits run in tandem, often servicing different sections or devices. Without labels, trying to pinpoint which circuit belongs to a specific area or function can quickly become a time-consuming hassle. Having a clear labeling system means that maintenance, upgrades, and troubleshooting can be done with efficiency, preventing unnecessary disruptions.

Think about a situation where a specific light fixture or power outlet needs servicing. Instead of spending precious time flipping breakers and testing which circuit controls what, a well-labeled system immediately provides the answer. For businesses where downtime equals lost revenue, this level of organization is invaluable. Proper labeling ensures that the right circuits are identified and isolated quickly, keeping operations running smoothly without unnecessary delays.

Meeting Code Requirements and Industry Standards

Electrical codes exist for a reason—they establish safety and consistency across all installations. Many local and national electrical standards require proper labeling for compliance, ensuring that electrical systems remain both safe and easily maintainable. Failing to follow these regulations can lead to issues down the road, whether it’s failing an inspection, facing fines, or having to redo entire sections of an electrical project.

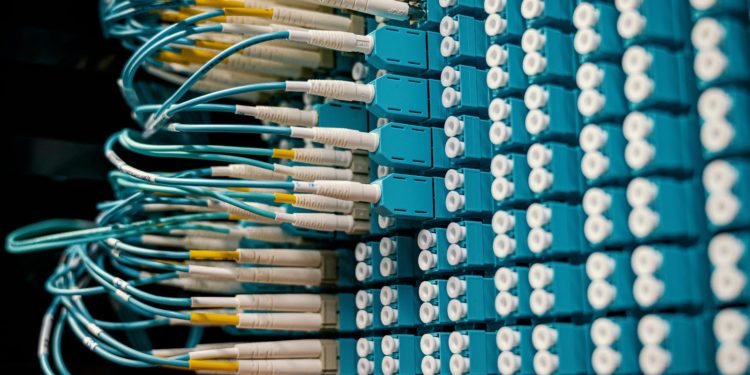

With standardized labeling, electricians can ensure their work meets regulatory expectations while also creating a more professional, user-friendly electrical system. From color-coded labels that indicate different functions to barcoded wire markers for easy digital tracking, labeling options have evolved to meet the diverse needs of various industries. This level of organization helps streamline both installation and future modifications, making it an essential step in any electrical project.

The Power of Customization

No two electrical systems are exactly the same, which is why customization is a key factor in wire labeling. Whether working on a residential property, a high-rise office building, or a manufacturing plant, labels can be tailored to fit specific needs.

Color-coded labels, for example, offer an easy visual distinction between circuits: red for emergency systems, blue for low-voltage wiring, yellow for high-voltage applications—the possibilities are endless. Meanwhile, pre-printed labels for HVAC systems, lighting controls, security systems, and data networks provide instant clarity, eliminating guesswork when working on complex setups.

For even greater efficiency, durable heat-shrink labels or self-laminating markers ensure that labels remain legible even in harsh environments. Weather-resistant labels can withstand extreme temperatures, moisture, and exposure to chemicals, making them ideal for outdoor or industrial applications. With the right labeling approach, electrical systems remain clear and accessible long after the initial installation is complete.

Investing in Long-Term Efficiency

It’s easy to overlook wire labels in the grand scheme of an electrical project, but their long-term benefits are undeniable. They save time, reduce errors, improve safety, and enhance the overall efficiency of electrical systems. For electricians, properly labeled wiring demonstrates professionalism and attention to detail. For homeowners and business owners, it offers peace of mind knowing that their electrical systems are well-organized and easy to maintain.

Whether upgrading an old electrical panel, wiring a new home, or managing an intricate commercial system, investing in a solid wire labeling strategy is a decision that pays off every time maintenance or troubleshooting is required. As technology advances and electrical systems grow more complex, clear labeling remains a simple yet powerful tool in keeping things running smoothly, safely, and efficiently.

So, the next time wires need to be organized, labeled, or sorted, taking the time to implement a thoughtful labeling system is one of the smartest moves to make. It’s a small step that makes a world of difference in the long run.

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)