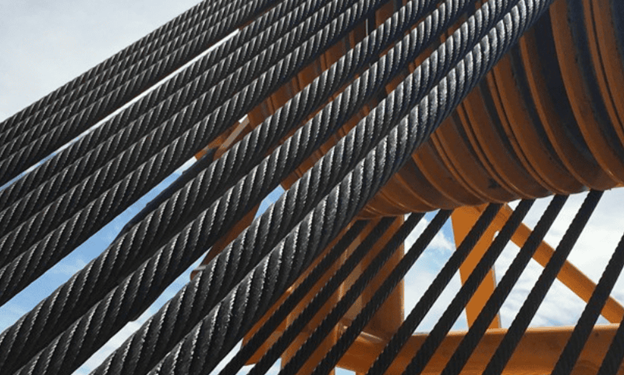

In todays industrial and construction industries, reliable cabling is an absolute must for efficiency. As with many of the electric and mechanical cables on offer, our range of niche cable and crane cable are critical to safety, performance and durability in extreme applications. These ropes are engineered to resist harsh environments, heavy loads and even repeated mechanical abrasion – truly a critical product in multiple industries.

What is Specialty Cable?

Specialty cable is any type of electrical or mechanical cable that is considered for a particular application in which standard types cannot satisfy the performance values. These cables feature special materials, insulation and construction techniques to ensure they retain their integrity when exposed to brutal elements, chemicals or extreme temperatures or mechanical stress.

Common Features of Specialty Cable

- High resistance to temperature variations

- Enhanced mechanical durability

- Chemical and oil resistance

- Flexibility for difficult installations

- Customizable designs for specific applications

Specialty Wire & Cable Specialty cable finds uses in industry including aerospace, medical, automotive and marine as well as industrial… Their signal integrity under adverse conditions, immunity to the effects of damage/corrosion, and long-term reliable operation in extreme environment scenarios make them an optimal solution on critical applications.

Applications of Specialty Cable

- Industrial Machine: Ensures dependable power and control connections on heavy machinery, robotics and automated equipment lines.

- Surgical Instruments/Imaging: The cables of these are made from quality metals for safe and reliable performance in precision instruments and imaging equipment.

- Marine and Offshore Applications: Specialty cables can handle saltwater, UV exposure and high temperatures to ensure they work when you need them – on ships and oil rigs.

- Aerospace and Defense: In the aerospace and defense industry, cables must meet intense vibration resistance, heat resistance and EMI / RFI requirements.

The right specialty cable enables industries to achieve superb operational efficiency, minimize downtime and improve safety in the workplace.

What is Crane Cable?

Crane cable, is a special cable for the powering and controlling of cranes and other related equipment. Constructed to withstand continuous flexing, chaining and even exposure to the elements on job sites, in ports or at manufacturing companies.

Key Features of Crane Cable

- Durable design won’t snap or break with repeated bending and twisting

- Strong tension to bear heavy weights

- For use in the toughest environments with abrasion and impact resistance

- Outdoor weather and oil resistant

- Long lasting insulation to prevent electrical leakage

Crane cable is offered in different sizes, conductor materials and jacket types to meet the unique needs of your particular crane, voltage and working conditions.

Applications of Crane Cable

Crane ropes are indispensable in industries or operations where heavy material lifting and moving is a necessity. Typical applications include:

- Sites of construction: In tower cranes, mobile cranes and gantry cranes to facilitate the efficient lifting and shifting of loads.

- Port Operations: Necessities for container cranes, dockside lifting equipment and ship loading systems.

- Factory/ Warehouse: To drive overhead cranes for lifting heavy machinery and materials.

- Mining and Heavy Industry: Employed in mining hoists, draglines, and other heavy machinery where resilience is paramount.

Selecting the correct crane cable will help minimize downtime from hydraulic or pneumatic working devices and improve worksite safety.

Advantages of Special and Crane Cables

Here is why: There are a number of benefits when using premium specialty cable and crane cable:

- Sturdy: Can survive under extreme conditions with heavy loads and frequent tugging.

- Protection: Preventvv electrical and mechanical damage.

- Performance: Provides consistent and reliable transmission of power.

- Savings: More money in your pocket for less replacements and cheaper maintaining.

- Customisation: Can be designed to meet requirements such as voltage, application and environment.

There is an investment in the correct type of cable for industrial and construction needs which promises longevity and reliability.

Selecting the right specialist or crane cable

There are different aspects you need to consider when choosing your cable:

- Position Requirements: Knowledge of the mechanical and electrical requirements of machines.

- Environment: Where will the sensor be used and what will it be exposed to – chemical, heat, moisture or outdoor elements?

- Flexibility/Bending Radius: Make Sure The Cable is Sufficiently Flexible for Frequent Bending and Flexing.

- Voltage and Capacity: The electrical specs of the cable must suit the equipment you are using.

- Industrial standards: Comply with international and local industrial safety standards applicable to industrial cables.

Contact an experienced specialty or crane cable manufacturer or supplier to help make your decision on the best performing specialty and crane cables for your application.

Conclusion

Specialty cable and crane cable are indispensable elements in a wide variety industrial, construction and production settings. They afford excellent flexibility, durability, and safety when ordinary cables can no longer perform. Knowing their characteristics, uses and advantages will enable businesses to make informed choices, avoid any downtime and operate safely and efficiently.

If you are running a construction site, a manufacturing plant or machinery with special-purpose equipment, the right choice of specialty as well as crane cable is crucial for long-time and successful operation!