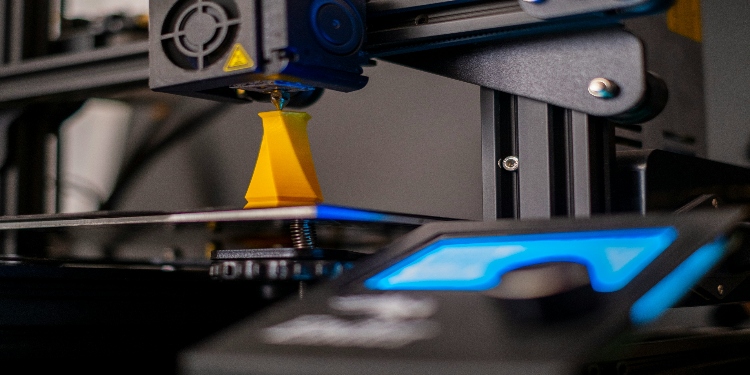

The price, accessibility, and variety of Fused Deposition Modelling (FDM) make it one of the most popular 3D printing methods. Even beginner and seasoned users frequently encounter difficulties with print quality, even though it is a great option for quick prototyping and producing working parts. Many factors can affect the final result, ranging from stringing and poor adhesion to warping and apparent layer lines. The good news is that you can greatly improve your FDM 3D printer’s print quality with the correct information.

We will go over important pointers in this blog that will help you get stronger parts, smoother finishes, and better outcomes all around.

1. Improve Bed Calibration and Levelling

An incorrectly levelled bed is one of the most frequent causes of poor print quality. The extruded filament cannot flow properly if the nozzle is too near the bed, which could result in blockages or rough first layers.

However, prints could not adhere to the build plate correctly if the nozzle is too far away. Consistent first layers, the cornerstone of excellent prints, are guaranteed by routinely calibrating the bed. Although many contemporary 3D printers have automatic bed levelling mechanisms, diligent manual calibration can also be successful.

- Ensure the Bed Adhesion Is Correct

To stop prints from bending or separating in the middle of the process, good bed adhesion is essential. You can use adhesives like glue sticks, painter’s tape, or specialty print surfaces to increase stickiness. It also makes a big difference to change the bed temperature according to the type of filament.

For example, it can need temperatures as high as 110°C, but PLA often adheres effectively around 60°C. Adhesion problems are also lessened by a bed that is spotless and devoid of grease.

- Adjust Print Speed

Print quality is directly impacted by print speed. Faster speeds save production time, but they frequently sacrifice precision and attention to detail. Surface finish can be greatly improved by reducing the print speed, particularly for top layers and outer perimeters.

Slowing down to 40-60 mm/s is recommended for complex models or those that need a lot of detail. Larger and less intricate prints, on the other hand, can be produced at faster speeds without suffering appreciable quality degradation.

- Change the Layer Height for Accuracy

A print’s resolution is determined by its layer height. Although they result in smoother surfaces and finer details, lower layer heights (0.1 mm) also lengthen print times. Faster but less detailed are higher layer heights (0.3 mm or more). The model’s intended use frequently determines the optimal layer height.

A larger layer height is effective for prototypes when aesthetics are not important. Smaller layer heights work great for complex pieces or presentation models.

- Keep the Extrusion Temperature at the Right Level

For reliable extrusion, the nozzle’s temperature is essential. A temperature that is too high can result in stringing, blobs, or even burned filament, while a temperature that is too low might result in weak layers and under-extrusion. To determine the sweet spot, always consult the manufacturer’s suggested temperature range for your particular type of filament and run tiny test prints.

Results can also be improved by engaging sophisticated printers with automated temperature calibration or by keeping a thermometer close at hand.

- Make Use of Proper Filament Quality

Filaments differ from one another. Impurities or diameter irregularities are frequently present in low-quality filaments, which can cause blockages, uneven extrusion, or poor adhesion. Better print quality and continuous flow are guaranteed when you invest in high-quality filament. Because moisture can cause filament to bubble and deteriorate print quality, proper filament storage is also essential. The integrity of the filament is maintained by storing it in sealed containers with desiccants.

- Improve Ventilation and Cooling

In order to preserve crisp details and harden the extruded filament, cooling is essential. Poor overhangs, stringing, and sagging might result from inadequate cooling. Results can be significantly improved by installing or updating part cooling fans, particularly for PLA and other similar materials. High cooling is advantageous for some filaments, but not for others.

Fan speeds should be adjusted according to the type of material because it is prone to warping under excessive cooling.

- Avoid Cracking and Warping

When a print warps, it pulls off the bed because the lower layers cool and compress more quickly than the top layers. Preserving constant temperatures, heated build plates, and bounded print chambers lessens warping. Using enclosures or draft shields around the printer helps maintain a steady environment and prevents materials like nylon and ABS from cracking due to abrupt cooling.

- Reduce Oozing and Stringing

The term “stringing” describes the tiny filament strands that are left over after the nozzle moves between various print areas. Retraction settings might be changed to lessen this problem. During travel moves, retractions keep the filament from leaking by drawing it back slightly into the nozzle.

Reduction of stringing can be achieved by increasing travel speed and adjusting retraction distance. This issue can be further reduced by making sure the nozzle temperature isn’t too high.

2. Maintain and Clean Your Printer

High-quality printouts start with a printer that is properly maintained. Clogs, uneven extrusion, and overheating problems can be avoided with routine cleaning of the nozzle, bed, and fans. While tightening belts stops layer shifting and wobbling, lubricating the moving parts guarantees smooth action. By keeping the printer in optimal condition, routine maintenance checks lower the likelihood of print failures.

- Upgrade Parts When Required

Print quality can occasionally be limited by the stock components of your 3D printer. By switching to an all-metal hot end, a greater variety of filaments can be printed at higher temperatures. When printing abrasive materials like carbon fibre, durability can be increased by switching out stock nozzles with hardened steel nozzles. The quality can be significantly improved even by adding auto bed levelling sensors or improving build surfaces.

- Think About Expert Services For 3D Printing.

Personal 3D printers are great for learning and modest tasks, but they frequently need specialised knowledge and sophisticated equipment to produce work of professional quality. Moreover, companies like CAD Deziners offer specialised 3D printing services in Sydney, which guarantee accurate and well-finished products without the trouble of a lot of trial and error.

Final Thoughts

Improving print quality in FDM 3D printing requires a combination of minor tweaks and regular upkeep rather than a one-step procedure. There are several ways to improve results, ranging from levelling the bed and adjusting the settings to upgrading gear and hiring a professional service.

Both professionals and enthusiasts can overcome typical printing obstacles and realise the full potential of FDM technology by comprehending and utilising these strategies. The pursuit of high-quality prints guarantees that your 3D printing adventure stays effective, fulfilling, and creative. CAD Deziners provides high quality 3D Printing Architectural Model In Australia, providing businesses, product designers, and innovators with access to cutting-edge machinery and skilled experts.