We welcome you to Hopeful, your go to partner for aluminum CNC machining services In China. We deliver precision crafted custom parts, and unparalleled service and accuracy at a competitive cost. With our advanced CNC machines and skilled technicians, you can expect your projects to be completed with utmost accuracy and efficiency.

For more in-depth information you should view from Aluminum CNC Machining Service – Hopeful

Industries in China consider Hopeful their preferred partner for aluminum CNC machining services because of.

You can expect precision and quality craftsmanship at every stage of the machining process whether its design or production. At Hopeful, we take pride in being the foremost provider of aluminum CNC machining services in China. Exceptional results from every machining project is guaranteed due to our sophisticated cutting tools and CNC machines. Coupled with extensive experience for working with various aluminum alloys, we are unmatched in the industry.View our blog, Is Aluminum Magnetic? Unraveling the Mysteries of Metal Magnetism – Hopeful for more details

In what ways do we advance CNC mill technology and how does it benefit your projects?

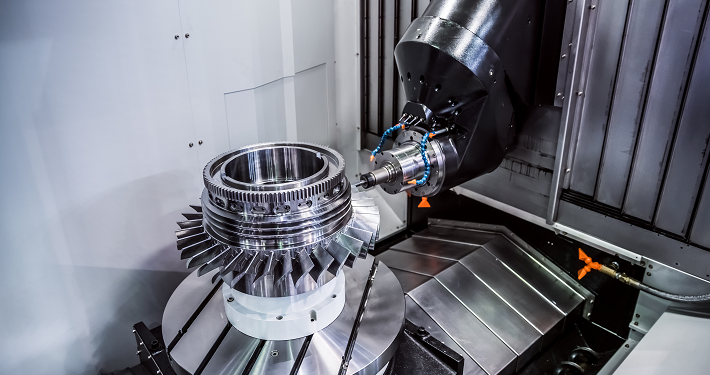

Our advanced CNC mill technology streamlines the processes in aluminum CNC machining, ensuring high efficiency and accuracy. We utilize both 3-axis and 5-axis CNC milling with the ability to carry out even the most geometrically complex designs. This technology allows us to manufacture custom aluminum parts with surfaces that meet demanding specifications in various industries, as well as provide tight tolerances.

Which aluminum alloys do we have in stock?

At Hopeful, we have an extensive variety of aluminum alloys to suit any project. We specialize in well known alloys such as aluminum 6061, aluminum 7075, aluminum 5052, aluminum 6063, aluminum 2024, and aluminum 7050. Each alloy has distinctly different properties including high strength to weight ratio, excellent machinability, and superior corrosion resistance. We help clients to select the most appropriate material to suit their needs so that the parts are durable and function as intended throughout their service life.

How do we go about achieving accuracy and maintaining standards in our machining operations?

For us, quality control begins in CNC machining. We conduct quality assurance activities from the beginning of production to machinery to raw materials, and even post-process to the final product. Every aluminum piece put through our machines is guaranteed to have the precise tolerances required through the skill of our seasoned machinists and the quality control processes in place, which utilize sophisticated measuring devices and techniques. To improve the appearance and properties of the finished parts, we also provide additional surface finish treatments, like anodizing.

What are the services offered by Hopeful in aluminum CNC machining?

Hopeful is our go to provider for any and all aluminum CNC machining services, and we are sure to fulfill your needs. This includes our offerings of custom CNC machining, CNC turning and CNC milling. These services are crafted to suit programing for small quantities of prototypes as well as big quantities for mass production, with guaranteed quality every step of the way regardless of the batch size. With these services, we can manufacture a broad variety of custom made aluminum parts, including simple parts and even complex assemblies.

What are the unique features of our 5-axis CNC mill working capabilities?

With our 5-axis CNC milling capability, we have changed the game for CNC machining of aluminum parts. This technology enables us to machine complex shapes and undercuts in one setup which saves time and improves accuracy. Achievement of detailed features and contours are easily accomplished with 5-axis CNC machining, whilst being difficult and sometimes impossible with conventional 3-axis machining and therefore is particularly beneficial for avionic and automotive industries which require the fabrication of lightweight, yet intricately designed components.

What are some key characteristics of our 3-axis operations?

Although versatile, our 5-axis machining is not the only service we offer; our 3-axis services are a long-standing staple in our company. 3-axis CNC machining works optimally on an extensive list of aluminum components due to its accuracy and efficiency. This machining process not only works best with less complex geometry, but is also ideal for mass production. With our advanced 3-axis milling machines coupled with our skilled engineers’ ability to fine-tune tool paths and cutting parameters, you are assured of timely delivery and affordable pricing on your machining projects.

Are we capable of managing both high and low volume production runs? Of course, at Hopeful’s machine shop, we are able to manage any production run size. If you need one prototype machined aluminum part, or 1000, our team is ready to help you. Thanks to our flexible manufacturing system, we can scale production without compromising quality from the first to last part. Our clients are part of the development of the production optimization-in-cost and delivery-time strategies to ensure work deadlines are met without losing quality.

How does Hopeful lower CNC machining prices without losing quality? Here at Hopeful, we know that cost-effectiveness has to be part of the quality of the final product and CNC machining. For that reason, we have different approaches to optimizing a specific machining process and lowering the costs of the final product. This includes employing advanced CAM software for toolpath generation, using high-speed machining, and lean manufacturing within our machine shop. All of this leads to lower machining time, lower material waste, and reduced costs for our clients.

What strategies do we use to improve the efficiency of the machining process?

When it comes to machining, having optimized processes is vital when trying to lower the cost involved in CNC machining aluminum with high quality. The use of advanced CAM software enables us to create sophisticated toolpaths that achieve high rates of material removal and low rates of tool wear. Our expert machinists carefully choose cutting tools and machining conditions so that the most favorable cycle time and surface finish are attained. Moreover, we are always investing in new milling machines and CNC routers with better accuracy and higher spindle speed, as these will allow us to provide even more cost efficient machining services.

How do we achieve both cost efficiency and excellent surface finish?

An excellent surface finish is essential in a number of applications and may increase the cost of CNC machining. At Hopeful, we maintain the desired quality surface finish while being cost efficient by thoroughly planning and executing every process. Our wide experience in aluminum CNC machining enables us to choose the appropriate cutting strategy, tool geometry, and machining parameters that will most likely yield successful results. Additionally, we can further enhance the aesthetic and functional properties of the machined aluminum parts by anodizing them without greatly increasing the overall cost.

How does our high-tech machine shop affect cost efficiency?

Our high technology machine shop greatly impacts our pricing competitiveness for aluminum CNC machining services. The purchase of advanced CNC equipment, such as multi-axis milling centers and high-speed CNC routers, allows us more accurate and quicker production leading to lower labor costs and higher standards of aluminum CNC machining. In addition, the orderly and productive layout of the machine shop reduces idle time and improves the speed at which work is done. These benefits ultimately allow us to offer lower prices to our clients.

What are the benefits of using aluminum to manufacture CNC machined components?

Aluminum is a useful metal for CNC machined parts because of its unique properties. Its alloys have an exceptionally high strength-to-weight ratio which makes them useful for weight sensitive parts like in the automotive and aerospace fields. Aluminum machining is more efficient because of its remarkable machinability and allows for faster cutting speeds with slower tool wear, leading to lower costs. In addition, aluminum is widely used for many industries due to its corrosion resistance and electrical conductivity.

What problems are solved by the use of aluminum 6061 and 7075 in CNC machining?

Aluminum 6061 and 7075 are among the highly used alloys for CNC machining, both having specific benefits. Its use as a structural material is mostly because of its excellent machinability, moderate strength, and good corrosion resistance. It is widely used in the manufacturing of custom parts for various industries. Aluminum 7075 on the other hand has superior strength and fatigue resistance, therefore it is used in aerospace and defense for high-stress applications. Both alloys are easily anodized for strengthening and better finishing of the products which improves mechanical as well as aesthetic properties.

In what ways do the mechanical properties of aluminum directly affect the performance of products?

Aluminum has a crucial role in the performance of CNC machined components owing to the mechanical properties it has. Aluminum alloys are known to have a very favorable strength-to-weight ratio which is ideal for components that need to be light in weight without compromising structural integrity and strength. Robust yet lightweight components can be manufactured which proves to be beneficial for the overall performance of the product. Aluminum’s excellent thermal and electrical conductivity permits its use for applications that need a shield for heat or electricity.

What us the benefit of using aluminum rather than other metals and plastics?

Aluminum outstands other metals as well as plastics in comparison to steel, which provides poor machinability in terms of cutting speed and surface finish. Other standard materials like plastics do not give the capability of withstanding greater thermal management, in comparison to aluminum. Aluminum is much more lightweight compared to steel as well, which increases its suitability for weight sensitive situations. Being able to anodize aluminum offers reinforced resistance to corrosion as well as alter its appearance. These positive attributes make aluminum an notable contender for CNC machined components in numerous sectors.

Which factors affect the pricing of aluminum CNC machining at Hopeful?

Pricing is affected by multiple considerations when it comes to CNC machining aluminum at Hopeful. For example, a part’s design may be complex, such as having features with tight tolerances, intricate geometries, and very thin walls, all of which have significant impacts on machining time and tool wear. A great deal of pricing also depends on the materials selected because different aluminum alloys are priced and can be machined quite differently. Surface finish requirements, modifications such as anodizing or heat treatment, and the quantity produced also have an effect. At Hopeful, we strive to meet our customer’s desires and, at the same time, maintain proper guidelines for efficient manufacturing while also ensuring high quality, which is why we use set pricing.

How does part complexity affect the cost of CNC machining?

CNC machining costs are affected by the complexity of the part to be machined. Deep, thin, and tight features often require specialized cutting tools and long machining times with multiple setups. Produced complex geometric features increase machining time and also may need advanced CAM programming and toolpath optimization. Complex parts are produced faster and at a lower cost with the utilization of advanced 5-axis CNC machining with design for manufacturing (DFM) at a Hopeful Company.

In what way does the choice of materials impact the pricing of a product?

The selection of materials is fundamental in setting the price of CNC machined parts. Different types of aluminum alloys have different prices based on their cost, ease of machining, and supply. Aluminum 6061, for example, is much cheaper and easier to machine than high-strength alloys, aluminum 7075 or 7050. Material selection tells much about the tooling costs and set parameters of machining, all of which have a say in production time and tool life. At Hopeful, we collaborate with our customers to suggest which aluminum alloy would yield the desired performance at the least possible expense.

How does design optimization aid in the reduction of costs for CNC machining aluminum?

Optimization is one of the strongest approaches available for reducing CNC machining costs of aluminum on a per-part basis while maintaining functionality. Using design for manufacturing (DFM) principles, we can recommend changes that enhance production along with part performance. These changes could include increasing wall thicknesses, placing reliefs on deep pockets, or relaxing tight tolerances where feasible. Our seasoned engineers can also suggest other design changes which take advantage of one or more of our highly automated CNC machines, and which may require fewer setups or allow better toolpaths to be used. All of these changes increase efficiency and significantly decrease the time and material wasted during machining processes, therefore, increasing overall savings.

Which industries are served by Hopeful’s aluminum CNC machining services?

Hopeful Aluminum LLC’s aluminum CNC machining services are meant for a variety of industries, all of which appreciate our precision-engineered components. We have excelled in meeting the aerospace industry’s requirements for lightweight and high-strength components that meet stringent industry standards. Additionally, we service portions of the automotive industry where precision surface finish and tight tolerances on both prototype and production parts are crucial. Our services in the medical industry also work towards the manufacturing of instruments and components of devices with precision. We also deal with manufacturers in the electronics industry who require housings and heat sinks for components with good thermal management. Moreover, we cater to clients in the defense, robotics, and consumer products industries which shows the extensive versatility of our capabilities in aluminum CNC machining.

How does the aerospace industry make use of the CNC machined aluminum parts we offer?

Our CNC machined aluminum parts are important for a number of uses in the aerospace industry. We focus on the manufacture of robust yet lightweight parts that aircrafts and spacecrafts require. We have extensive experience with high strength aluminum alloys such as 7075 and 7050, which enables us to produce aerospace grade components. Structural components, precise brackets and other fittings are a few examples of our precision machined aluminum parts that enhance the safety and functionality of aerospace vehicles. For corrosion protection and durability improvement, which are essential in aerospace surface treatments, we are able to provide anodizing as well as other special processes.

Which sectors do we service in the automotive field?

We service numerous sectors in the automotive field with our aluminum CNC machining capabilities. We CNC machine custom aluminum parts for both prototypes and production runs, from competitive racing parts to everyday automobile parts. We also manufacture lightweight engine parts, transmission cases, suspension pieces, and chassis components. Using aluminum in these components helps to lower the weight of the car, which improves fuel economy and performance. Our exceptional surface finishes and ability to meet stringent tolerances allows us to service the automotive industry’s exacting standards.

In what ways do our services cater to the needs of the medical and electronics industries?

Our CNC aluminum machining services assist in the fabrication of diagnostic instruments, surgical tools, and components of medical devices in the mainstream medicine field. Certain alloys of Aluminum are not only biocompatible, but also exhibit corrosion resistance, making them useful in a number of medical conditions. The ability to maintain stringent tolerances and fabricate intricate features enables us to support the production of prosthetic limbs and diagnostic machines. In the electronics sector, we manufacture housings, heat sinks, and chassis components. Since aluminum has exceptional thermal conductivity, it is beneficial for managing heat in electronic devices. We are able to design custom cooling devices that dissipate heat effectively, contributing to optimum performance and durability of the electronic components.

What is the standard lead time for aluminum CNC machined parts?

Lead times generally differ depending on the complexity and number of parts that need to be machined. However, our standard orders normally have a turnaround time of 5 to 10 business days. For more urgent projects, rush services are available.