Ultrasonic welding has transformed into a basic system in the collecting of clinical contraptions, offering a trustworthy and successful procedure for joining materials. This communication uses high-repeat ultrasonic acoustic vibrations to make solid state welds, meaning the materials are joined without the necessity for additional pastes or power, making it ideal for applications where precision and sterility are essential.

How Ultrasonic Welding Capabilities

Ultrasonic welding deals with the standard of changing over electrical energy into mechanical vibrations. The cooperation incorporates four essential parts:

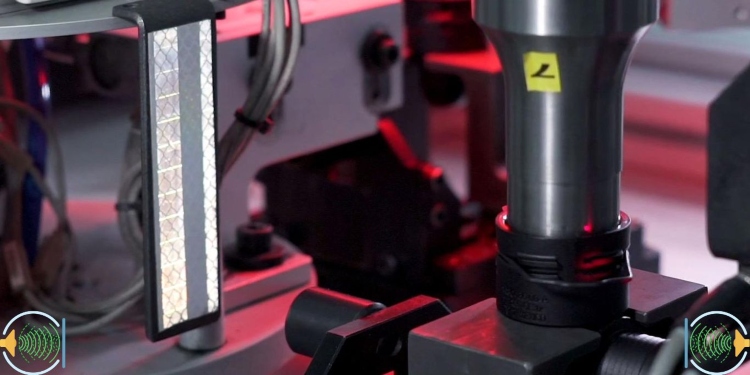

Transducer: Converts electrical energy into high-repeat ultrasonic vibrations.

Ally: Improves the vibrations delivered by the transducer.

Horn (Sonotrode): Guides the vibrations to the materials being welded.

Metalworker’s iron: Supports the materials and helps focus the energy for effective welding.

Right when the ultrasonic vibrations are applied to the materials, they make restricted heat on account of disintegration, causing the materials to unwind and bond together. The entire cooperation occurs quickly, making it an astoundingly compelling method for collecting.

Advantages of Ultrasonic Welding in Clinical Device Gathering

Precision and Consistency: Ultrasonic welding offers unmatched exactness, which is crucial in the collecting of clinical devices. The communication considers tight control over the limits, ensuring consistent weld quality across colossal creation runs.

Sterility: considering the way that ultrasonic welding requires no external power or concretes, it restricts the bet of corrupting. This is particularly huge in clinical device delivering, where keeping a sterile climate is basic.

Material Likeness: Ultrasonic welding is reasonable with numerous materials, including plastics and a couple of metals. This flexibility makes it fitting for collecting different clinical devices, from unnecessary things like needles to extra confounded contraptions like catheters.

Speed and Efficiency: The cycle is fast, habitually requiring several minutes to complete a weld. This speed, got together with the ability to mechanize the communication, makes ultrasonic welding significantly capable, diminishing creation time and costs.

Normal Impact: Ultrasonic welding is an unblemished communication that doesn’t convey harmful releases or waste. This lines up with the creating complement on reasonability in collecting practices.

Utilizations of Ultrasonic Welding in Clinical Devices

Ultrasonic welding is extensively used in the production of clinical contraptions where high precision and sterility are required. A couple of typical applications include:

Superfluous Clinical Things: Things, for instance, blood channels, facial covers, and IV catheters are by and large welded using ultrasonic advancement. The collaboration ensures a safeguarded seal without compromising sterility.

Implantable Devices: Ultrasonic welding is used to assemble implantable contraptions like pacemakers and speakers, where exactness and strength are essential.

Indicative Stuff: The collecting of logical instruments, for instance, ultrasound tests and other handheld devices, similarly benefits by ultrasonic welding, which gives strong and trustworthy joints.

Challenges and Considerations

While ultrasonic welding offers different benefits, it similarly presents explicit hardships:

Material Assurance: Not all materials are proper for ultrasonic welding. Producers ought to circumspectly pick practical materials to achieve ideal results.

Joint Arrangement: The arrangement of the joint expects a critical part in the result of the welding framework. Genuine arrangement ensures that the ultrasonic energy is consistently scattered, achieving solid areas for a.

Equipment Costs: While the cycle is capable, the basic interest in ultrasonic welding stuff can be high. Regardless, the long save subsidizes in progress costs and waste abatement regularly offset the hidden expense.

FAQs

1. What sorts of materials can be welded including ultrasonic welding in clinical device manufacturing?

Ultrasonic welding is suitable with different thermoplastics and a couple of metals. Typical materials consolidate polyethylene, polypropylene, and certain composites. The choice of material depends upon the specific application and the essential properties of the finished contraption.

2. Is ultrasonic welding okay for use in sterile circumstances?

For sure, ultrasonic welding is perfect for use in sterile circumstances. The cooperation needn’t bother with pastes or outside heat sources, which decreases the bet of polluting. Likewise, the welding framework itself is perfect, conveying no damaging releases.

3. How does ultrasonic welding diverge from other welding methods concerning speed and capability?

Ultrasonic welding is out and out faster and more capable than various other welding methodologies. The cycle consistently requires several minutes to get done with, making it ideal for high-volume creation. Likewise, the ability to motorize the cycle further develops adequacy and diminishes work costs.

End

Ultrasonic welding has shown to be a significant advancement in the collecting of clinical contraptions. Its ability to give precise, sterile, and capable welds makes it fundamental in an industry where quality and security are first. Correspondingly as a ultrasonic homogenizer is principal for making uniform mixes in research habitats, ultrasonic welding is fundamental for ensuring the dependability of clinical contraptions. As clinical contraption manufacturing continues to progress, ultrasonic welding is presumably going to expect an irrefutably critical part in ensuring that things satisfy the most raised rules of execution and faithful quality.

David Prior

David Prior is the editor of Today News, responsible for the overall editorial strategy. He is an NCTJ-qualified journalist with over 20 years’ experience, and is also editor of the award-winning hyperlocal news title Altrincham Today. His LinkedIn profile is here.

![7 Best POS Software in the UK [2026 Edition]](https://todaynews.co.uk/wp-content/uploads/2026/02/7-Best-POS-Software-in-the-UK-2026-Edition-360x180.png)