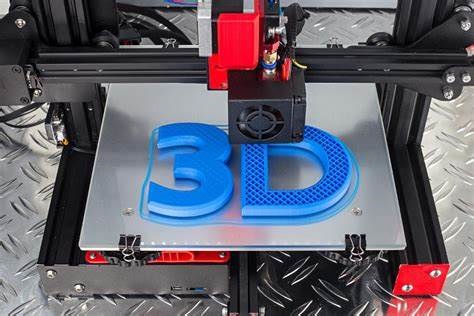

When magical thinking and rapid prototyping are central to many industries, online 3D printing services have changed the business and the way how enthusiasts implement their projects. No longer do precise replica parts need to be produced through heavy industry setups. The design process has become widespread. This blog intends to review the working environment of the online 3D printing services, how these platforms function, what type of materials and technologies are incorporated in their work, and how to choose the right platform. Getting to these perspectives qualifies the reader to reason out sensibly and in line with what the specific undertaking requires.

For more in-depth information you should view the Top 3D Printing Service Provider in China – Kingsun

What is a 3d print Service?

Understanding the Environment of 3D Print Services

3D printing is the process, also called as additive manufacturing, in which objects are created gradually from a number of materials like plastics, metals, resins, etc. This tuition amount at every stage implements digital 3D objects considered to be the lifework of the printing process. Stereolithography, selective laser sintering, and fused deposition modeling are representative of separate techniques within 3D printing and employ different materials and produce different designs as gravity depends upon the material used and the level of accuracy associated with the structure. Rather the accuracy and versatility of the 3D print technology allow making up shapes and details which hard-to-make with conventional manufacturing.View Top 3D Printing Service Provider in China – Kingsun for More Details

How Online 3D Printing Service Works

A 3D printing service will allow customers to upload their designs onto a platform that would provide them different types of materials and printing technologies. Typically, these services include easy to use interfaces which help the clients in the selection so that the end product is able to meet the required technical specifications and functionalities. When one order the print units, the order processing goes forward to 3D approbation by pricey printers in their service centers. The ordering for the significantly complicated and custom-designed printed parts can take many days, printing seems to bring perfect turnaround times with ideal vertical integration in place.

Types of 3D Print Services Available The landscape of 3D print services encompasses a wide range of options catering to different needs and industries.

Available 3D printing services are vast and directed to specific needs and areas of industry. Rapid prototype services provides fast Visible prototyping per design of functionality. Tailor-made production services assist in the production of low volume but complex products. In addition, some sites offer only certain types of technologies such as industrial metal 3D printing or artistic projects which require high detail resin 3D printing. When it comes to choosing the right type of service, such aspects as type of material, quality of prints, lead time and price efficiency have to be taken into account as all those aspects are critical towards project’s success.

What are the 3D Printing How to choose the right 3D printing material?

These all require how to be selective to a material to help guarantee success.

Different 3d printing materials explained In making comparison between the various 3D printing techniques one of the most determinant is 3D printing materials.

Gentle, space and comparing of metal 3D printing and plastic opportunities.

The selection of the 3D printing materials influences greatly the mechanical strength, surface finish and suitability of the final product for its intended application. These are the most common materials:

PLA (Polylactic Acid): The bioplastic source from renewable biological products that has problems when using in hot environments does not pose a problem, they are easy to work with as are low-cost materials with reasonable surface finishes.

While ABS (Acrylonitrile Butadiene Styrene): is a thermoplastic based on petroleum that is considered strong, flexible, tough and stable but high temperatures are essential in order to print it.

Polyamide: High strength-to-weight ratio and flexibility are its prominent attributes and thus finds utility in functional components which require shock resistance.

Materials such as printing resins: The printing resin materials used in SLA printing are mainly flexible or tough with variants for high definition images.

Materials including but not limited to metals: Stainless steel, aluminum, and titanium which is used for mail boxes made for high strength and high temperatures.

Factors Influencing Material Choice

There are various considerations when selecting 3D printing materials:

Mechanical Properties: Requisites such as tensile strength, flexibility, impact resistance and others influence the general scope of materials used based on properties and applications at hand.

Surface Finish: Particularly for highlighting certain aspects of projects contact surfaces or edges materials such as resins or plastic are harnessed.

Environmental Impact: Friendly to the environment projects look for alternatives such as PLA which are biodegradable.

Cost: Due to cost limitations some materials like PLA which are cheaper than metals will be used.

Application: Considering the final product, is it just a prototype, functional components, or artistic forms influences the choice of materials.

Comparison between Metal 3D Printing and Plastic 3D Printing

There are benefits and demerits for both metal and plastic 3D printing and each has its own field of specialization:

Metal 3D Printing: This is the best for products which are involved a lot of wear and tear and high accuracy is required since a complex form can be created and maintain good strength properties. The drawback is that the cost is usually high, and installation of oriented facilities may be a requirement.

Plastic 3D Printing: Cost effective and most importantly more versatile with different fields, plastic options can be used for parts that may require less mechanical strength like rapid prototyping tools and end use parts. They usually enable simpler operations following the printing as well as shorter lead times.

Choosing metal over plastic or vice versa is hinged on budget, performance requirements and what the project entails either in engineering or aesthetics design.

How Can One Get A 3d printing quote?

How to Get a Pricing and Ordering With the Online Service Immediately

Choose Platform: Clients can get an instant quote by using any of the available 3D printing online service providers that are efficient and where order placement is online.

Upload Your Design: Before proceeding to upload, have your 3D model file saved in either STL or OBJ format.

Choose Material and Process: State the material and 3D printing method to be used on your project, dictating on cost, surface finish, and durability.

Enter Quantity and Size Parameters: Provide the number of parts to be made together with the appropriate sizes so as to obtain accurate prices.

Review and Submit: All information related to instant billing should be cross checked and found to be correct to allow the submission of the request.

Details that are Necessary to Provide a Fair 3D Printing Quote

3D Model File: For accurate pricing details a well constructed and properly formatted three dimensional design is very important in the estimation of price.

Material Choice: Clearly identify what the material will be and any specific characteristics such as color or finish.

Production Volume: Provide what would be the number of units needed because bulk orders may be money savers.

Post-Processing Needs: State any additional work components like polishing or painting that may influence the pricing.

Delivery Timeline: Indicate how long within the time frame the items are to be delivered because rush orders may cost more.

Tools to Calculate 3D Printing Service Cost

Cost Estimation Software: Software applications that help to integrate factors like material volume, printing time and manual work to cost out the price comprehensively.

Online Calculators: Online calculators which provide a preliminary analysis of expected expenses based of a submitted design.

Material Cost Database: Databases containing various materials and respective prices, which can help determine cost alternatives.

Print Simulation: Simulation software that helps examine the print job in terms of performance and efficiency as well as in print cost reduction through trimming of the design.

3D Printing Advantages: What Are They?

Advantages of 3D Printing Technology

Thus, it follows that any production sphere offers distinct advantages brought about by the use of 3D printing technologies. For example, there is a significant reduction of time and material involved in the creation of models, resulting in cost savings and reduced waste. Tolerance level and usage of the products are improved and enhanced respectively since the products can be designed to target particular needs. This reduces the timescale to manufacture products, especially, by not needing to go through conventional tools, hence speeding up the full cycle of creating a product.

Application in Different Industries

3D printing technology is used in various industries changing the ways of generating and assembling items. In the medicine industry, it is mostly used to prepare personalized medicines, make prostheses and implants as well as planning surgeries with organ models. 3D printing is applied in manufacturing rapid prototypes of complex and lightweight elements which will improve the performance and reduce fuel consumption of cars and planes. Furthermore, the technology is progressing in the industry of fashion enabling the creation of complex and new designs that could not be achieved by conventional methods.

Comparison with Traditional Manufacturing

Among the benefits that add an additional level, when 3D printing is used design logic structures issued an advantage over normal manufacturing methods. More and most often is, particularly if connected to cutting materials where there end up no good consequences, so all other ways are eliminated to the present method known as the 3D Printing where it resorts to only building up what is just enough. This in turn will save time and help in curbing the eco negative impact. Also 3D printing gives relatively easy access to unlimited product design enabling even complex structures that cannot be practically possible for conventional methods with less expenses. With 3D printing, these are easier to make models but producing them on a large scale tends to be cheaper through conventional means than plastic processes because of growth and efficiency of the framework system.

Find out the Way to Purchase 3D Models and Details in Work

Process of Ordering 3D Models via the Internet

Locate a Service Provider: To obtain the model that you require, find and evaluate a reliable internet 3d model printing and emitting company. Look for the features such as the available materials, the time frames, and the rate of customer satisfaction.

Open an Account: Sign up in the site to make it easier to communicate with the service provider and track the orders made. In this stage, basic personal details are provided and a password is set in order to complete the registration process.

Select Your Material and Finishing Options: Check out the offered materials and pick out the one that suits your design best. Certain platforms have various kinds of finishes where you can practically enhance some aspects of your model.

Uploading and Preparing Your 3D Model

File Format Check: Make certain that the format of your 3D model file is compatible. The format could either be STL, OBJ or 3MF, which includes a client .BOW .TFC .3D 360 .STF. Each service may have their own considerations, confirm before uploading.

Model Verification: Try utilizing some primary structures on the figure which can show you even minor details of the construction and its areas of interests such as borrowers or internal partitions. Moreover, there are also things that you should not forget how to repair any fault caused by those works for instance printing of sintered pieces.

Scaling and Orientation: Reduce or expand the dimensions of your model to ensure meeting the requirements set out for the project and make sure that the model is positioned appropriately in order to reduce the amount of support structures and enhance the amount of strength.

Understanding the 3D Printing Process

Slicing: The model will be sliced into layers, so-called, in order to prepare it for 3D printing as intended. Each layer will contain a cross section of the object and will be processed considering the niobium path for the filament deposition head movement.

Print Settings Adjustment: The scaling of the structure, composition of the external head, and composition of supportive girders need attention during the printing stage. These parameters influence the operational characteristics of the object, the quality of its manufacture, and the duration of the printing process.

Quality Assurance: After the printing of the model, a review is done regarding the printed model to ensure that no mistakes are made in regard to the printed design. A service provider may provide additional services, including limpieza or smoothing, model surface finishes to the model.

Particularly, if you understand how the process of placing an order is done, and how to make sure you receive only the best quality 3D printed models, it will be very easy for you to make and get orders that will meet your expectations.